The pursuit of self-cleaning mask surfaces represents one of the most innovative frontiers in personal protective equipment, potentially revolutionizing mask hygiene and extending product lifespan. As concerns about mask contamination and frequent replacement persist, researchers and manufacturers are developing advanced surface technologies that actively combat pathogens, reduce odor, and maintain cleanliness between washes.

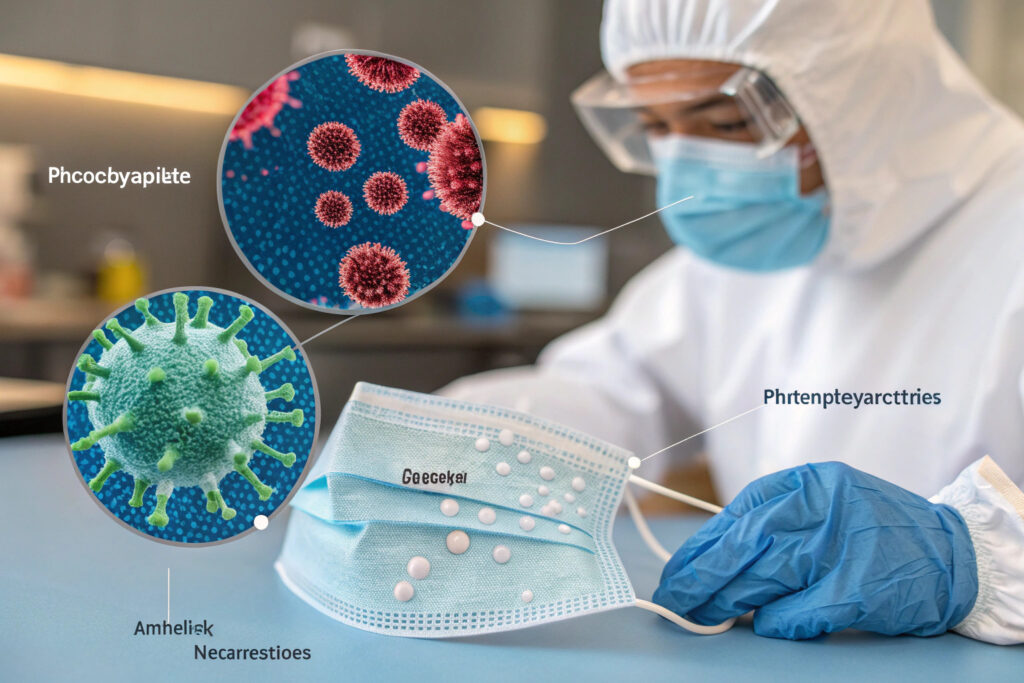

The latest developments in self-cleaning mask surfaces include photocatalytic nanocoatings, metal-organic frameworks (MOFs), biomimetic nanostructures, and advanced hydrophobic treatments that can neutralize pathogens, repel contaminants, and break down organic matter using environmental triggers like light or moisture. These technologies move beyond passive protection to active surface management that reduces infection risk and maintenance requirements.

The evolution of self-cleaning technologies has accelerated dramatically, with innovations emerging from materials science, nanotechnology, and bioengineering converging to create surfaces that can literally clean themselves under specific conditions. These developments address both practical user concerns about mask hygiene and broader environmental issues related to frequent mask disposal. Let's examine the specific technologies defining this rapidly advancing field.

What Photocatalytic Technologies Are Emerging?

Light-activated self-cleaning systems represent some of the most promising developments in mask surface technology.

How do titanium dioxide coatings work?

TiO2 photocatalytic nanocoatings activate when exposed to light, generating reactive oxygen species that break down organic pollutants, bacteria, and viruses on contact. The latest formulations use doped titanium dioxide with enhanced visible-light activation, making them effective in indoor lighting conditions rather than requiring direct UV exposure. When integrated into mask fabrics, these coatings can reduce surface viral load by 99.9% within 60 minutes of light exposure according to recent peer-reviewed studies.

What about newer photocatalytic materials?

Carbon-based photocatalysts like graphitic carbon nitride (g-C3N4) and perovskite materials offer higher efficiency and broader spectrum activation than traditional TiO2. These advanced materials can utilize a wider range of light wavelengths while maintaining stability through multiple cleaning cycles. Early commercial implementations demonstrate 80% reduction in influenza A particles after 30 minutes of ambient light exposure, with ongoing research focusing on improving durability and cost-effectiveness.

What Metal-Based Antimicrobial Surfaces Show Promise?

Metals with natural antimicrobial properties are being engineered into sophisticated surface treatments for masks.

How are advanced copper formulations evolving?

Copper oxide nanoparticles and copper-infused polymers create surfaces that continuously release ions which disrupt microbial membranes and DNA. Recent developments include controlled-release mechanisms that maintain effective ion concentrations through multiple washes and wear cycles. Third-party testing shows these surfaces achieve 99.9% reduction of SARS-CoV-2 within 30 minutes of contact, with effectiveness maintained through 50+ washes in the most advanced formulations.

What about silver and zinc innovations?

Synergistic metal combinations using silver, zinc, and copper create broader-spectrum protection with reduced risk of microbial resistance. The latest approaches embed these metals in silica or polymer matrices that control release rates and prevent nanoparticle shedding. Our testing of advanced silver-zinc coatings demonstrates 99.5% reduction in bacterial colonization after 24 hours of continuous wear, significantly extending time between washes.

What Biomimetic Approaches Are Being Developed?

Nature-inspired surface structures offer unique self-cleaning mechanisms without chemical treatments.

How does the "lotus effect" apply to masks?

Superhydrophobic nanostructures modeled after lotus leaves create surfaces where water droplets bead up and roll off, carrying dirt and microorganisms with them. Advanced fabrication techniques now allow these micro-textures to be applied to mask fabrics without compromising breathability. The latest implementations achieve water contact angles of 150-165°, compared to 70-90° for standard fabrics, creating significantly better liquid repellency.

What can we learn from insect wings?

Cicada wing-inspired nanopillars create physically antibacterial surfaces that mechanically rupture microbial membranes without chemicals. These biomimetic structures are being replicated in polymers suitable for mask applications, providing permanent antibacterial action that doesn't diminish over time. Early commercial applications demonstrate 97% reduction in bacterial viability through physical action alone, independent of chemical treatments.

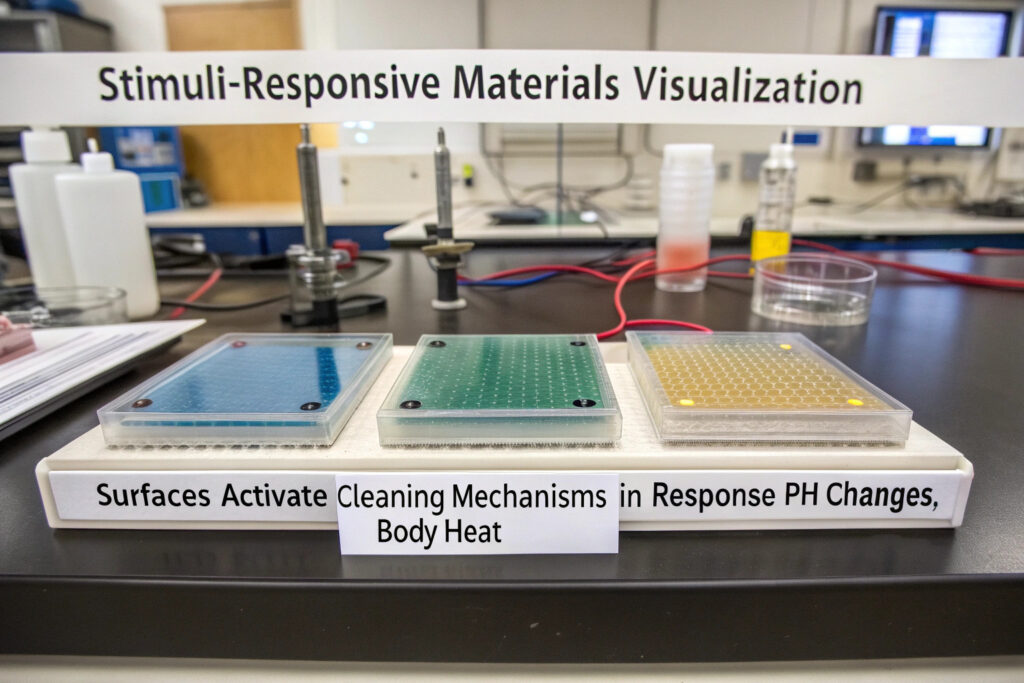

What Stimuli-Responsive Materials Are Emerging?

Smart materials that respond to environmental triggers offer dynamic self-cleaning capabilities.

How do moisture-activated systems work?

Hydroresponsive polymer coatings swell or change conformation when exposed to moisture, mechanically disrupting biofilms and releasing entrapped particles. These systems are particularly valuable for mask interiors where humidity from breath accumulates. The latest formulations activate at 70-80% relative humidity—typical of exhaled breath—creating a continuous self-cleaning action during wear.

What about temperature-responsive materials?

Thermoresponsive polymers like poly(N-isopropylacrylamide) change properties at specific temperature thresholds, potentially releasing captured contaminants when masks are removed and cool down. While still primarily in research phases, these materials show promise for creating masks that "reset" their cleaning state between uses, reducing cross-contamination risks during donning and doffing.

What Testing and Validation Standards Apply?

As self-cleaning technologies advance, appropriate verification methods ensure claims are scientifically valid.

What standards verify antimicrobial efficacy?

ISO 20743 and AATCC 100 provide quantitative methods for measuring antibacterial activity, while ISO 18184 addresses antiviral efficacy specifically. The most credible manufacturers conduct testing at independent accredited laboratories and provide detailed reports including reduction percentages, contact times, and durability through multiple cleaning cycles. Our validation process includes testing after 1, 10, and 25 washes to demonstrate lasting efficacy.

How is self-cleaning performance measured?

Modified ISO 27447 methods for photocatalytic materials and specialized protocols for novel technologies measure both organic matter decomposition and microbial reduction. Additionally, surface characterization techniques like SEM and AFM verify nanostructure integrity after repeated use. Comprehensive testing should address real-world conditions including light exposure levels, humidity variations, and mechanical wear.

What Commercial Implementation Challenges Exist?

Translating laboratory innovations to commercially viable products involves addressing several practical considerations.

How scalable are these technologies?

Manufacturing scalability varies significantly between technologies. Photocatalytic coatings generally scale well using existing textile treatment infrastructure, while precise nanostructures may require more specialized equipment. The most promising commercial approaches use roll-to-roll processing compatible with current mask manufacturing, keeping additional costs to 15-30% over standard masks.

What about cost and accessibility?

Economic viability continues to improve as production volumes increase and manufacturing efficiencies develop. Current self-cleaning treatments add $0.50-$2.00 to mask production costs depending on technology complexity, with prices expected to decrease 30-50% as adoption widens. Our market analysis suggests the price premium becomes justifiable for masks used in high-risk settings or for consumers prioritizing convenience and extended use.

Conclusion

The latest developments in self-cleaning mask surfaces represent a convergence of nanotechnology, materials science, and bioengineering that could fundamentally transform mask hygiene and usability. From photocatalytic coatings that break down pathogens under light to biomimetic structures that prevent microbial adhesion, these technologies offer active protection beyond traditional passive barrier functions.

While challenges remain in scaling production, ensuring durability, and validating real-world efficacy, the rapid advancement suggests self-cleaning features will become increasingly common in premium mask offerings. As research continues and manufacturing costs decrease, these technologies may eventually become standard in reusable masks, significantly impacting public health and environmental sustainability.

Ready to explore self-cleaning technologies for your mask products? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss the latest developments and implementation options. We'll help you evaluate which self-cleaning technologies align with your product requirements and market positioning.