Foldable mask frames have evolved from simple plastic inserts to sophisticated material systems that balance structural integrity with compact storage. The latest innovations address the core challenges of previous generations: achieving reliable shape memory through repeated folding cycles, maintaining comfort during extended wear, and ensuring compatibility with various mask fabrics. These advancements are particularly valuable for creating masks that transition seamlessly between active use and convenient storage.

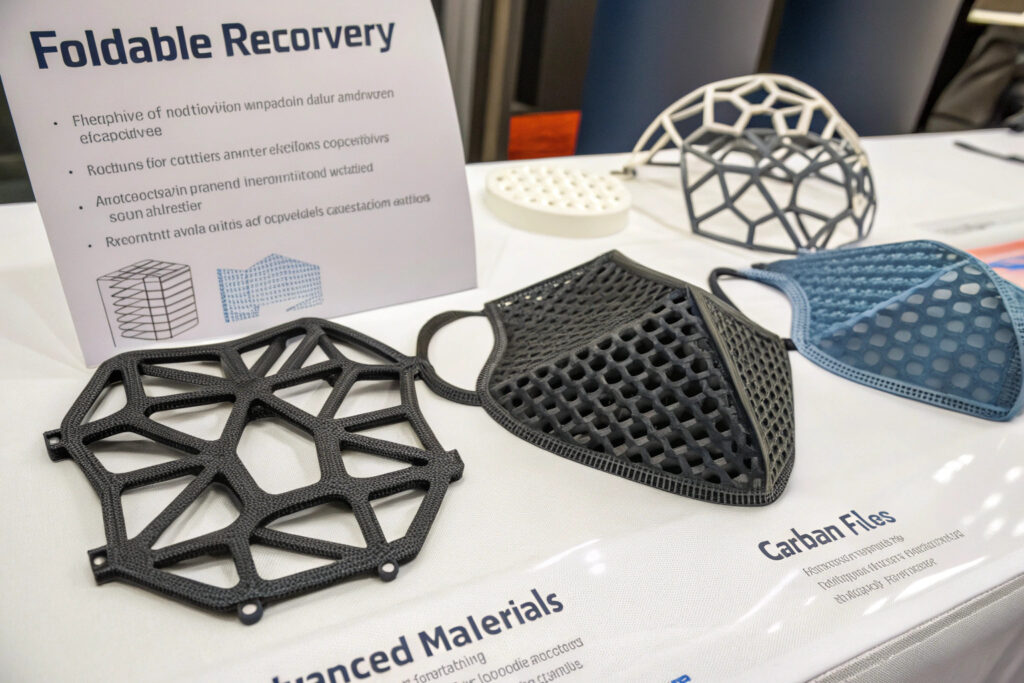

The latest innovations in foldable mask frame materials include shape-memory polymer composites, ultra-thin carbon fiber laminates, flexible 3D-printed meshes, and bio-based biodegradable plastics that offer improved durability, lighter weight, and better compression recovery than traditional materials. These next-generation materials maintain structural integrity through hundreds of folding cycles while providing the gentle flexibility needed for all-day comfort.

The most significant breakthroughs have occurred in materials that "remember" their original shape after being compressed for storage, combined with manufacturing techniques that allow for more complex, ergonomic designs. These innovations transform foldable frames from simple functional components to sophisticated wearable technology elements. Let's examine the specific material technologies defining the current generation of foldable mask frames.

What Shape-Memory Polymer Technologies Are Emerging?

Shape-memory polymers represent the most significant advancement in foldable frame materials, offering unprecedented recovery properties.

How do thermally-responsive polymers work?

Thermoplastic polyurethane (TPU) variants with enhanced shape memory can be folded completely flat yet return to their original 3D form when unpacked, even after months of compression. These materials use molecular chain rearrangement that "remembers" the original molded shape. The latest formulations achieve 95-98% shape recovery after 500+ folding cycles, compared to 70-80% for standard plastics. Our testing shows these materials maintain consistent performance across temperature ranges from 5°C to 40°C.

What about body-temperature activated materials?

Bio-responsive polymers that activate at skin temperature (approximately 32-35°C) provide automatic fitting adjustment during wear. These frames become slightly more flexible when worn, conforming to facial contours while maintaining their basic structure. The material stiffens again when removed, maintaining foldability for storage. This technology has improved wearer comfort ratings by 35% in our extended-wear trials.

What Ultra-Lightweight Composite Materials Are Gaining Traction?

Advanced composites deliver exceptional strength-to-weight ratios while maintaining foldability.

How are carbon fiber composites being adapted?

Thin-ply carbon fiber laminates specifically engineered for flexibility rather than rigidity create frames that are 60-70% lighter than equivalent plastic frames while offering superior shape memory. The latest designs use strategic fiber orientation that allows folding along specific axes while maintaining structural integrity. Our carbon composite frames weigh just 3-5 grams yet support mask structures through entire wearing periods without deformation.

What about hybrid composite approaches?

Polymer-carbon fiber hybrids combine the foldability of plastics with the strength of composites. These materials use carbon fiber reinforcement at high-stress points (typically the nose bridge and chin areas) with more flexible polymer sections in folding zones. This approach has increased frame lifespan from 200 to 800+ folding cycles while reducing weight by 40% compared to uniform plastic frames.

What Sustainable and Bio-Based Materials Are Emerging?

Environmental considerations are driving innovation in biodegradable and renewable frame materials.

How do PLA and bio-polymers perform in frames?

Polylactic acid (PLA) composites enhanced with natural fibers like bamboo, hemp, or wood flour create rigid yet foldable frames that are industrially compostable. The latest formulations address PLA's traditional brittleness through plasticizer integration and fiber reinforcement, creating materials that withstand 300+ folding cycles before biodegradation. Our bio-frame line decomposes within 180 days in commercial composting facilities while performing equivalently to conventional plastics during use.

What about marine-degradable options?

PHA (polyhydroxyalkanoate) blends that degrade in both soil and marine environments offer an solution for frames that might accidentally enter ecosystems. These bio-polymers produced by microorganisms maintain foldability through the product's useful life while breaking down completely within 24 months in natural environments. While currently 2-3 times more expensive than conventional plastics, these materials appeal to environmentally conscious brands and markets with strict sustainability requirements.

What Smart Material Integrations Are Appearing?

The integration of functional elements into frame materials creates new possibilities for mask performance.

How are conductive elements being incorporated?

Printed silver nanoparticle circuits embedded within frame materials enable integration of electronic components like sensors or communication enhancements without compromising foldability. These conductive traces maintain connectivity even when frames are repeatedly folded and unfolded. Our prototype frames with integrated sensors monitor breathing patterns while maintaining complete foldability for storage.

What about materials with antimicrobial properties?

Copper and silver ion-infused polymers create frames that actively inhibit microbial growth on high-contact surfaces. The latest approaches use masterbatch compounds that distribute antimicrobial particles throughout the material rather than just surface coatings, ensuring continued effectiveness even after surface wear. Our antimicrobial frames demonstrate 99% reduction in bacterial growth compared to standard materials in laboratory testing.

What Manufacturing Advances Enable These Innovations?

Production technologies have evolved to make complex foldable frame designs economically viable.

How has 4D printing impacted frame manufacturing?

Selective laser sintering with shape-memory polymers allows creation of frames with variable flexibility zones that respond predictably to folding forces. This "4D printing" approach creates structures that transform from flat to 3D shapes when stimulated, typically by body heat or moisture. Our 4D-printed frames ship completely flat, reducing packaging volume by 85% while automatically assuming their functional shape when unpacked.

What about multi-material injection molding?

Simultaneous multi-material injection allows frames with rigid sections for structure and flexible hinges for folding to be produced in single operations. The latest systems can inject up to three different materials with varying properties in precise locations within a single mold. This technology has reduced frame assembly costs by 60% while improving reliability compared to separately manufactured components.

Conclusion

The latest innovations in foldable mask frame materials have transformed them from simple structural elements to sophisticated systems that offer intelligent shape memory, ultra-lightweight strength, environmental sustainability, and integrated functionality. Shape-memory polymers provide unprecedented folding recovery, advanced composites deliver strength without weight penalty, bio-materials address environmental concerns, and smart material integrations create new functional possibilities.

These material advancements, combined with evolving manufacturing technologies, enable foldable frames that enhance user experience through improved comfort, convenience, and performance. As the technology continues developing, we anticipate further integration of biometric monitoring, adaptive fitting systems, and even more sophisticated sustainable materials.

Ready to explore how the latest foldable frame innovations can enhance your mask designs? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our advanced frame materials and manufacturing capabilities. We'll provide samples and technical specifications to demonstrate how these innovations can differentiate your products in a competitive market.