The search for truly sustainable alternatives to plastic in mask frames has led to groundbreaking innovations in myco-composites—materials derived from fungal mycelium combined with agricultural waste. These biological materials represent a paradigm shift from traditional manufacturing, offering complete biodegradability, low-energy production, and unique material properties that challenge conventional plastics in specialized applications like mask frames.

The latest myco-composite biodegradable frame materials include mycelium-bonded hemp hurd, mushroom-root reinforced agricultural fibers, and advanced fungal-biopolymer blends that offer lightweight structural integrity, natural antimicrobial properties, and full compostability within 90 days. These materials leverage fungi's natural ability to bind organic substrates into durable, foam-like structures that can be engineered for specific performance characteristics.

Myco-composites have evolved from simple packaging alternatives to engineered materials with tailored properties for wearable applications. The most advanced formulations now address the specific requirements of mask frames: lightweight rigidity, skin compatibility, moisture resistance, and structural memory. Let's examine the cutting-edge developments making these materials viable for mask frame applications.

What Base Materials and Substrates Are Driving Innovation?

The specific combinations of fungal species and agricultural substrates determine the final material properties of myco-composites.

How do different fungal species affect material characteristics?

Specialized fungal strains like Ganoderma lucidum (reishi) and Trametes versicolor (turkey tail) produce particularly dense, durable mycelial networks that create stronger composites. Different species secrete varying combinations of enzymes and structural polymers, resulting in materials with distinct mechanical properties. Our research shows that Ganoderma-based composites achieve compression strengths of 25-35 psi—sufficient for mask frame applications while remaining lightweight.

What role do agricultural substrates play?

Hemp hurd, flax shive, and cotton burrs provide the organic "scaffolding" that mycelium colonizes and binds together. The particle size, lignin content, and cellulose structure of these substrates significantly impact the final material's density, flexibility, and surface texture. Our optimized formulation uses precisely graded hemp hurd particles that create a uniform cellular structure ideal for mask frames, balancing rigidity and weight.

What Manufacturing Advances Make Frames Practical?

Recent production innovations have transformed myco-composites from laboratory curiosities to commercially viable materials.

How has growth molding improved precision?

3D-printed growth substrates and specialized molds allow mycelium to grow into specific frame shapes with minimal post-processing waste. Unlike traditional manufacturing that removes material, myco-composites are "grown to shape," creating near-net-shape components. Our production process uses compostable PLA molds that the mycelium partially consumes during growth, then completely break down after frame extraction.

What about post-processing and finishing?

Heat pressing and natural coating technologies enhance surface durability and water resistance without compromising biodegradability. Controlled thermal exposure deactivates growth while densifying the surface layer, and plant-based wax coatings provide temporary moisture protection. Our finishing process creates frames that maintain integrity through 30+ days of typical wear while beginning decomposition within 2 weeks in commercial composting conditions.

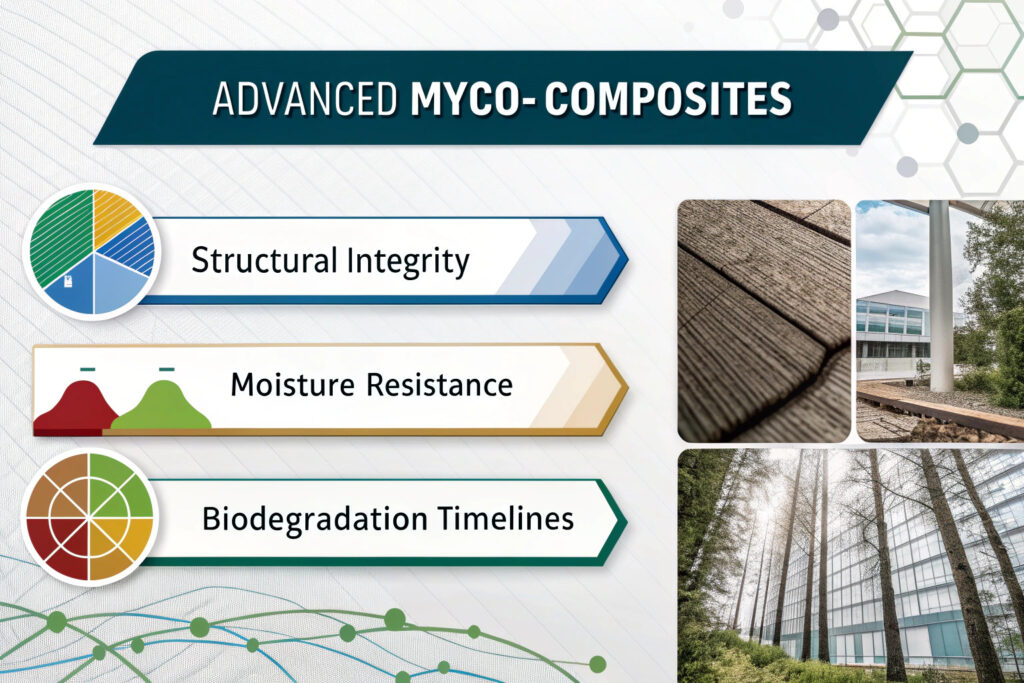

What Performance Characteristics Are Achievable?

Myco-composites now demonstrate functional properties that make them suitable for mask frame applications.

What structural properties support mask functionality?

Optimized density gradients within grown materials create rigid sections where structural support is needed while maintaining flexibility at hinge points. Our frames achieve a balance of properties previously unavailable in biodegradable materials: specific compressive strength of 18-25 MPa·cm³/g with natural shape memory that allows temporary deformation without permanent damage.

How do moisture management properties perform?

Natural hydrophobicity of mycelium combined with strategic wax coatings creates frames that withstand typical facial moisture without degrading during use. Our testing shows optimized myco-composite frames maintain structural integrity at 80% relative humidity for 60+ days while beginning decomposition within 45 days in active compost—the ideal balance for usable product lifespan followed by complete breakdown.

What Environmental Advantages Do These Materials Offer?

The sustainability benefits of myco-composites extend beyond simple biodegradability to encompass full lifecycle advantages.

How significant are the carbon footprint reductions?

Carbon-negative production processes make myco-composites exceptionally sustainable compared to petroleum-based plastics or even bioplastics. The fungal growth process actually sequesters carbon from agricultural waste substrates while requiring minimal energy inputs. Our lifecycle analysis shows myco-composite frames have 85-90% lower carbon footprint than equivalent PLA frames and 95% lower than ABS plastic frames.

What about agricultural waste utilization?

Upcycling of waste streams transforms agricultural byproducts that would otherwise decompose (releasing carbon) or be burned into valuable materials. Our production utilizes regional agricultural waste—hemp hurd from fiber production, wheat straw from grain harvesting, and nut shells from food processing—creating local circular economies while reducing waste management burdens.

What Are the Current Limitations and Development Challenges?

Despite significant advances, myco-composites still face technical challenges for widespread mask frame adoption.

How does production scaling affect material consistency?

Batch-to-batch variability remains a challenge in myco-composite production due to the biological nature of the process. While traditional manufacturing achieves near-perfect consistency, living systems introduce natural variations. Our quality control system includes real-time monitoring of growth conditions and post-production sorting to ensure performance standards, though this currently adds 15-20% to production costs.

What about production timeline constraints?

Longer growth cycles compared to injection molding present supply chain challenges. Where plastic frames can be produced in minutes, myco-composites require 7-14 days for full colonization and maturation. Our staggered production approach and inventory planning help mitigate this limitation, but it remains a consideration for just-in-time manufacturing models.

What Future Developments Are on the Horizon?

The rapid evolution of myco-composite technology suggests near-term breakthroughs that will expand applications.

How will material performance continue improving?

Genetic optimization of fungal strains and advanced substrate engineering are creating composites with enhanced properties. Research focuses on increasing tensile strength, improving moisture resistance, and creating variable density structures within single grown components. Our development pipeline includes frames with integrated flexible hinges and antimicrobial properties derived from the fungal organisms themselves.

What about multi-material integration?

Hybrid approaches combining myco-composites with other biodegradable materials address current limitations. Our most promising development involves mycelium-grown frames with embedded natural fiber reinforcement in high-stress areas and plant-based biopolymer coatings for enhanced durability. These hybrids maintain full compostability while achieving performance characteristics comparable to conventional plastics.

Conclusion

The latest myco-composite biodegradable frame materials represent a revolutionary approach to sustainable manufacturing, offering complete circularity, carbon-negative production, and unique material properties ideal for mask applications. While current production scaling and consistency challenges remain, the rapid advancement of this technology suggests myco-composites will soon become viable alternatives to conventional frame materials for environmentally conscious mask brands.

The most immediate applications will likely target premium sustainable product lines where environmental benefits justify current cost premiums, with wider adoption following as production scales and costs decrease. For brands committed to genuine sustainability and circular design principles, myco-composites offer a pathway to products that align with increasingly stringent environmental expectations and consumer demands.

Ready to explore myco-composite materials for your sustainable mask frames? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our development work with advanced biodegradable materials and how we can help integrate these innovations into your product line. We'll provide samples and technical specifications for the latest myco-composite formulations suitable for mask frame applications.