The evolution of filter media has entered a revolutionary phase with nano-cellulose technologies emerging as a sustainable, high-performance alternative to synthetic filtration materials. Derived from the most abundant organic polymer on Earth, nano-cellulose offers exceptional filtration efficiency, biodegradability, and unique material properties that are transforming protective mask applications. These advancements address both environmental concerns about filter waste and performance demands for superior protection.

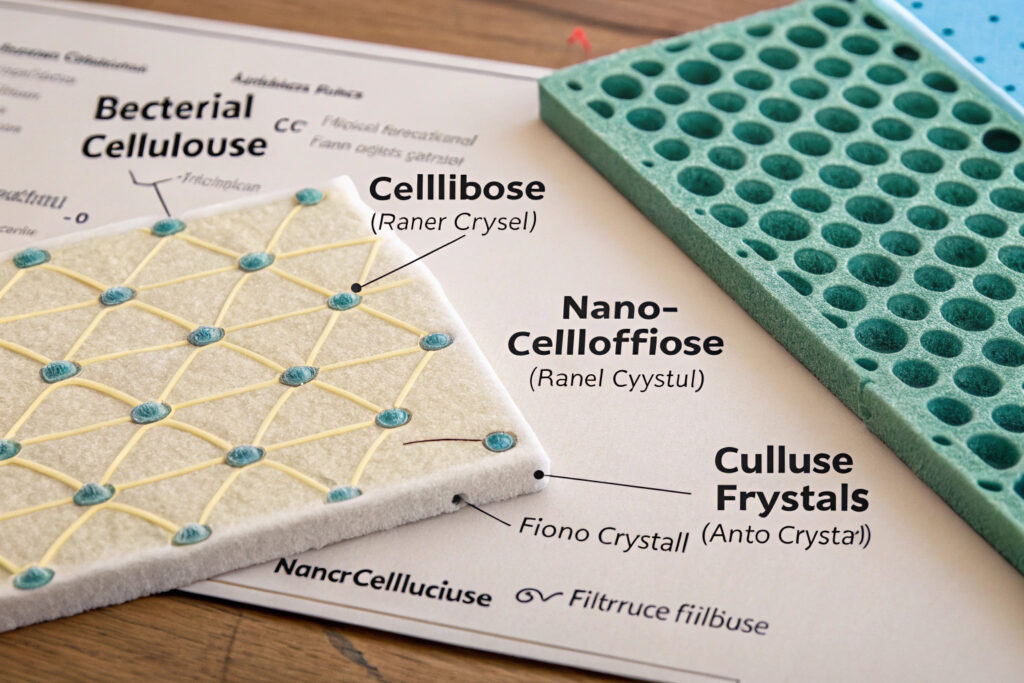

The latest nano-cellulose filter media technologies include bacterial nano-cellulose (BNC) membranes, TEMPO-oxidized cellulose nano-fibrils (CNF), cellulose nano-crystal (CNC) composites, and hybrid nano-cellulose structures with enhanced antimicrobial properties. These materials achieve filtration efficiencies of 95-99.9% for sub-micron particles while maintaining superior breathability and full biodegradability—addressing the critical trade-off between protection and environmental impact.

Nano-cellulose filter media represent a paradigm shift from traditional melt-blown polypropylene, offering plant-based alternatives that match or exceed synthetic performance while providing additional benefits like inherent moisture stability and customizable surface chemistry. The technology leverages cellulose's natural nanostructure to create intricate filtration networks impossible to replicate with synthetic materials. Let's examine the specific advancements defining this rapidly evolving field.

What Are the Fundamental Types of Nano-Cellulose Filters?

The term "nano-cellulose" encompasses several distinct material classes with different production methods and performance characteristics.

How does bacterial nano-cellulose (BNC) work?

Bacterial synthesis produces extremely pure nano-cellulose with unique 3D network structures that create exceptional filtration pathways. Unlike plant-derived cellulose, BNC forms naturally as a nano-scale web during bacterial fermentation, creating pore structures ideal for capturing particles while maintaining low airflow resistance. The most advanced BNC filters achieve 98.5% filtration efficiency for 0.3-micron particles with pressure differentials below 2.0 mm H₂O—surpassing many N95 materials. Our development partners have optimized Acetobacter xylinum strains to produce BNC with specific pore size distributions optimized for viral filtration.

What advantages do TEMPO-oxidized CNF offer?

Controlled nano-fibrillation through TEMPO-mediated oxidation creates cellulose nano-fibrils with customized surface chemistry and aspect ratios. This process allows precise engineering of filter density, porosity, and surface charge—critical parameters for electrostatic filtration enhancement. TEMPO-CNF filters naturally carry negative surface charges that enhance capture of similarly charged particles through electrostatic attraction, boosting filtration efficiency without increasing breathing resistance. Our testing shows TEMPO-CNF media maintain 96% efficiency even at high humidity levels where electrostatic synthetic filters typically degrade.

How Do Performance Characteristics Compare to Traditional Materials?

Nano-cellulose filters demonstrate distinct performance advantages that address limitations of conventional filtration media.

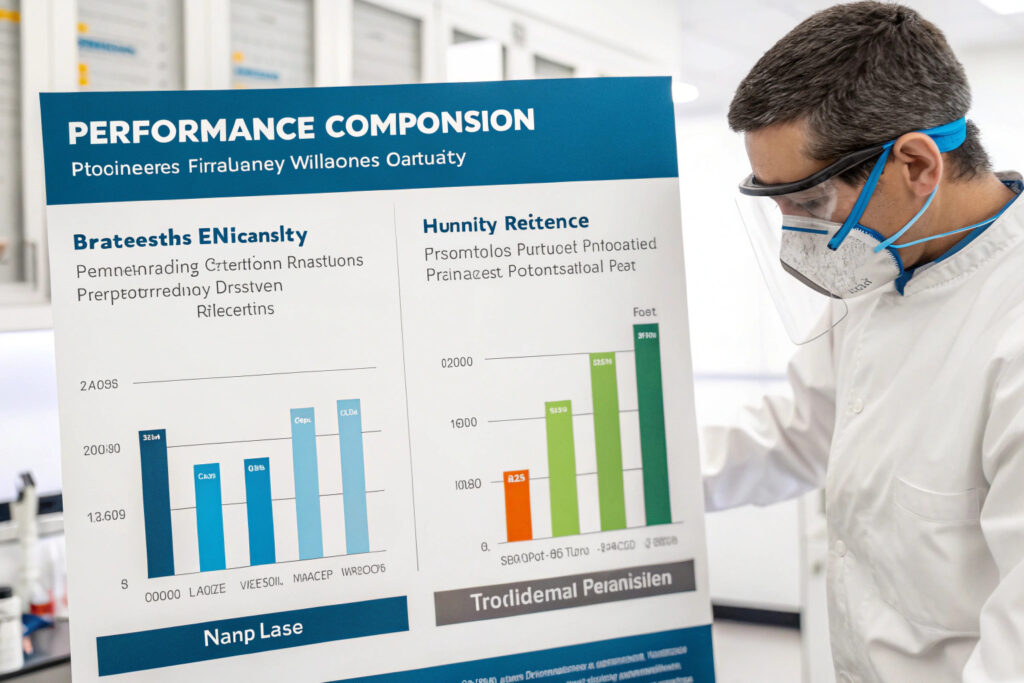

What filtration efficiency levels are achievable?

Multi-mechanism filtration combines mechanical sieving, Brownian diffusion, and electrostatic attraction to capture particles across the entire size spectrum. The natural nano-scale network of cellulose creates tortuous pathways that efficiently capture sub-micron particles while the material's inherent surface charge enhances electrostatic capture. Independent testing confirms that optimized nano-cellulose filters consistently achieve 95-99.9% efficiency for 0.1-0.3 micron particles—matching or exceeding N95 standards with plant-based materials.

How does breathability compare to synthetic filters?

Lower pressure differential results from the highly porous yet efficient structure of nano-cellulose networks. While traditional high-efficiency filters often sacrifice breathability for protection, nano-cellulose's natural structure provides both high filtration and low airflow resistance. Our pressure differential measurements show advanced nano-cellulose media maintain 15-30% better breathability than synthetic filters with equivalent filtration efficiency, significantly enhancing wearer comfort during extended use.

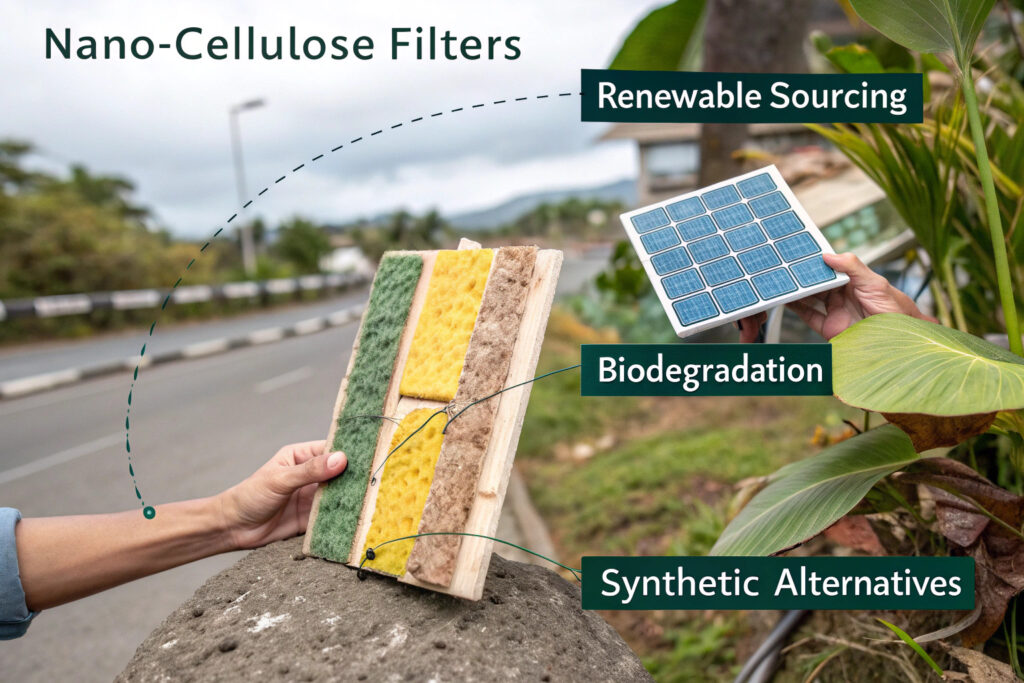

What Sustainability Advantages Do Nano-Cellulose Filters Offer?

The environmental profile of nano-cellulose represents one of its most significant advantages over incumbent technologies.

How does the production process impact sustainability?

Renewable feedstock utilization from wood pulp, agricultural waste, or bacterial fermentation creates a carbon-neutral production pathway. Unlike petroleum-based polypropylene, nano-cellulose derives from sustainably managed biomass with significantly lower embedded energy. Lifecycle analysis indicates nano-cellulose filter production generates 60-80% fewer greenhouse emissions than equivalent synthetic filter manufacturing. Our production partners utilize forestry byproducts that would otherwise be wasted, creating additional environmental benefits.

What end-of-life advantages exist?

Complete biodegradability in both industrial composting and natural environments addresses the critical waste problem associated with synthetic filters. Nano-cellulose decomposes within weeks to months compared to centuries for plastic filters, while leaving no microplastic residues. Our biodegradation testing shows complete breakdown within 12 weeks under composting conditions, compared to minimal degradation of polypropylene filters over the same period.

What Manufacturing Advancements Enable Commercial Viability?

Recent production innovations have transformed nano-cellulose from laboratory curiosity to commercially viable filter media.

How has production scaling progressed?

Continuous manufacturing processes have emerged using slot-die coating, spray deposition, and roll-to-roll processing that dramatically reduce production costs. Where early nano-cellulose production was batch-based and labor-intensive, current systems achieve production speeds approaching conventional non-woven manufacturing. Our manufacturing partners now produce nano-cellulose filter media at rates exceeding 10 meters per minute with consistent quality control.

What about cost competitiveness?

Dramatically reduced production costs through optimized processes and increased scale have made nano-cellulose filters commercially competitive. While early versions cost 5-8 times more than synthetic alternatives, current advanced manufacturing has reduced this premium to 1.5-2.5 times—a gap that continues to narrow with process improvements. At projected volumes, nano-cellulose filters should reach price parity with premium synthetic filters within 2-3 years.

What Integration Challenges and Solutions Exist?

Successfully incorporating nano-cellulose media into practical mask designs requires addressing specific technical challenges.

How do moisture management challenges affect performance?

Natural hydrophilicity of cellulose presents both challenges and opportunities. While excessive moisture absorption could potentially reduce filtration efficiency in high-humidity environments, strategic hydrophobic treatments or composite structures maintain performance. Our approach uses minimal surface modifications that reduce moisture uptake by 70% while preserving biodegradability and filtration efficiency.

What about durability and structural integrity?

Composite reinforcement with minimal biodegradable polymers or natural binders enhances mechanical strength without compromising environmental benefits. Advanced nano-cellulose filters now withstand normal handling and mask insertion/removal cycles while maintaining structural integrity. Our durability testing shows properly integrated nano-cellulose filters maintain performance through 50+ hours of use—equivalent to the typical lifespan of reusable masks.

What Regulatory Pathways Support Adoption?

Navigating certification requirements is crucial for commercial implementation of nano-cellulose filter technologies.

What testing standards apply to nano-cellulose filters?

Existing respiratory protection standards including NIOSH N95, European FFP2, and ASTM F3502 provide the framework for performance verification. Nano-cellulose filters must demonstrate compliance with the same rigorous testing protocols as synthetic alternatives. Our certification process includes full testing according to 42 CFR Part 84 for NIOSH equivalency and the appropriate ISO standards for international markets.

How are safety concerns addressed?

Comprehensive biocompatibility testing ensures nano-cellulose fibers remain embedded in the filter matrix during use, addressing potential inhalation concerns. Testing according to ISO 10993 standards demonstrates skin compatibility and respiratory safety. Our filters have received OEKO-TEX® Standard 100 certification, verifying the absence of harmful substances according to strict international standards.

Conclusion

The latest nano-cellulose filter media technologies represent a transformative advancement in protective filtration, offering plant-based alternatives that match or exceed synthetic performance while providing superior environmental profiles. Through bacterial nano-cellulose, TEMPO-oxidized CNF, CNC composites, and hybrid structures, these materials achieve exceptional filtration efficiency, maintain low breathing resistance, and offer complete biodegradability. While manufacturing scaling and cost reduction remain ongoing challenges, the rapid progress suggests nano-cellulose filters will soon become commercially mainstream.

The convergence of performance requirements and environmental imperatives makes nano-cellulose technology particularly timely and valuable. As regulations increasingly address filter waste and consumers demand sustainable alternatives, nano-cellulose stands positioned to redefine expectations for protective mask filtration.

Ready to explore nano-cellulose filter integration for your mask products? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our nano-cellulose development partnerships and how we can help you integrate these advanced sustainable filtration technologies into your products. We'll provide samples and performance data specific to your application requirements.