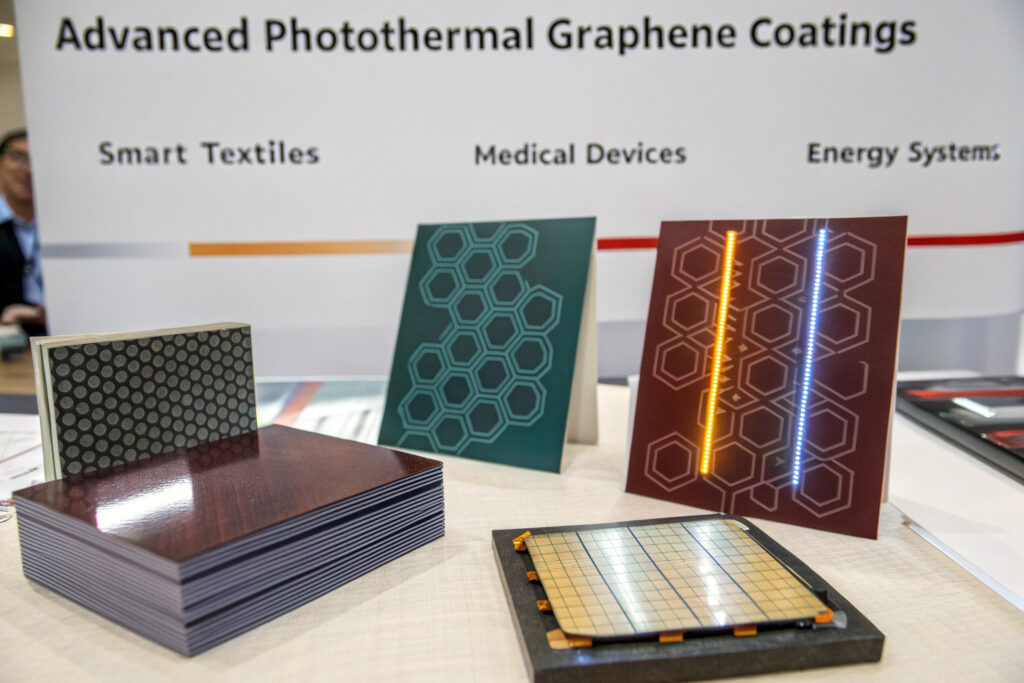

The integration of advanced nanomaterials into functional coatings has revolutionized thermal management across industries. Photothermal graphene coatings represent a particularly transformative technology, harnessing light energy to generate and control heat with unprecedented efficiency. For manufacturers in sectors ranging from smart textiles to medical devices and energy systems, understanding these latest coating technologies is key to developing next-generation products with active thermal regulation capabilities.

Photothermal graphene coatings are advanced functional surfaces that utilize graphene and its derivatives to efficiently convert light (particularly in the near-infrared spectrum) into thermal energy, enabling rapid, localized, and controllable heating without traditional electrical resistance elements. These coatings leverage graphene's exceptional light absorption, thermal conductivity, and electrical properties to create surfaces that can self-heat under illumination, respond dynamically to light intensity, and integrate with smart control systems. The latest advancements focus on improving conversion efficiency, enhancing durability, enabling low-temperature processing, and creating multifunctional composites.

The global graphene coating market is projected to reach $2.9 billion by 2030, with photothermal applications driving significant growth. Research in Nature Nanotechnology demonstrates that optimized graphene-based coatings can achieve photothermal conversion efficiencies exceeding 90% while maintaining flexibility and environmental stability. Let's explore the most significant recent developments in photothermal graphene coating technologies.

What Graphene Material Forms Deliver Optimal Photothermal Performance?

The specific form of graphene used in coatings—from reduced graphene oxide to pristine graphene flakes—significantly impacts photothermal efficiency, processing requirements, and final properties.

How Does Reduced Graphene Oxide (rGO) Compare to Pristine Graphene?

Reduced Graphene Oxide (rGO) has become the workhorse for commercial photothermal coatings due to its balanced performance and processability. The reduction process (thermal, chemical, or photonic) restores much of graphene's conjugated sp² carbon network, enabling strong broadband light absorption—especially in the near-infrared (NIR) region where sunlight and many artificial sources peak. While its thermal conductivity (approximately 500-1000 W/mK) is lower than pristine graphene (~3000-5000 W/mK), it is still exceptional and sufficient for most coating applications. Crucially, rGO disperses well in various solvents and polymer matrices, enabling solution-based coating techniques like spray, dip, or roll-to-roll application. According to research in Carbon, optimized rGO coatings can achieve a temperature increase of 40-60°C under 1 sun illumination (1 kW/m²).

What are the Advantages of Hybrid Graphene-Metal Nanoparticle Systems?

By decorating graphene sheets with plasmonic metal nanoparticles (like gold nanorods, silver nanostars, or copper sulfide), researchers create hybrid coatings with enhanced and tunable photothermal response. The nanoparticles exhibit localized surface plasmon resonance (LSPR)—a collective oscillation of electrons that strongly absorbs light at specific wavelengths. By controlling nanoparticle size and shape, the absorption peak can be tuned to match specific light sources (e.g., 808 nm or 980 nm lasers for medical therapy). Graphene acts as an excellent substrate, efficiently conducting the heat generated by the nanoparticles across the coating. Studies in ACS Nano show that graphene-gold nanorod hybrids can achieve photothermal conversion efficiencies over 95% at specific wavelengths, significantly outperforming either material alone.

What Advanced Manufacturing and Application Methods Are Emerging?

The transition from lab-scale demonstrations to industrially viable coatings requires scalable, reproducible, and cost-effective application methods that preserve graphene's properties.

Can Spray Coating and Inkjet Printing Enable Patterned Heating?

Yes, additive manufacturing techniques are revolutionizing photothermal coating application. Graphene-based inks, formulated with appropriate binders and dispersants, can be sprayed, inkjet-printed, or aerosol-jet printed onto substrates. This allows for:

- Patterned Heating: Creating intricate, localized heating zones (e.g., heating coils, logos, or therapeutic patches) without masking.

- Graded Coatings: Applying varying thicknesses to create temperature gradients.

- Conformal Coatings: Covering complex, 3D surfaces uniformly.

The key challenge is ink formulation—achieving stable dispersion, appropriate viscosity, and good adhesion after curing. Companies like Vorbeck Materials and Haydale are commercializing such inks. Our development uses a polyurethane-based rGO ink for spray coating textiles, achieving uniform heating with less than 10% temperature variation across 1m² areas.

How Does Layer-by-Layer Assembly Enhance Control and Functionality?

Layer-by-Layer (LbL) assembly is a versatile technique for building ultra-thin, multifunctional coatings with nanometer precision. By alternately dipping a substrate into solutions of positively and negatively charged materials (e.g., positively charged polyethyleneimine and negatively charged graphene oxide), a tailored coating is built up. This method allows for:

- Precise Thickness Control: Heating response can be tuned by the number of bilayers.

- Multifunctionality: Different layers can incorporate additional agents (e.g., antimicrobials, corrosion inhibitors).

- Excellent Adhesion: The electrostatic bonding creates strong interfacial adhesion.

Research in Langmuir indicates that LbL-assembled graphene coatings exhibit superior mechanical stability under flexing compared to many single-layer coatings.

What Multifunctional Composite Coatings Are Being Developed?

The latest research integrates photothermal graphene with other materials to create coatings that do more than just generate heat—they become interactive, responsive systems.

How Do Phase-Change Material (PCM) Composites Manage Thermal Energy?

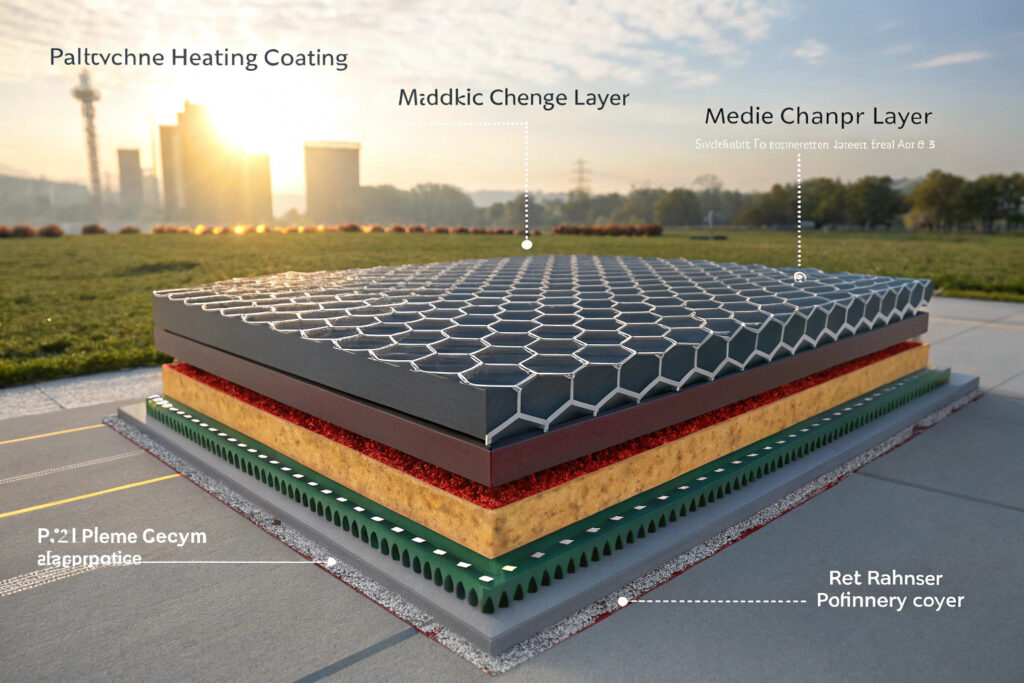

A major advancement is combining photothermal graphene with Phase-Change Materials (PCMs) like paraffin wax or fatty acids. In these composites:

- Graphene's Role: Efficiently converts light to heat.

- PCM's Role: Absorbs and stores that heat as latent heat during its solid-to-liquid phase change, acting as a thermal buffer.

This creates a coating that not only heats up quickly but also maintains a relatively constant temperature for extended periods after the light source is removed, preventing overheating and improving energy efficiency. For example, a graphene/paraffin coating on a building facade can store solar heat during the day and release it at night. According to studies in Energy Storage Materials, such composites can increase effective heat utilization time by 300-500%.

Can Coatings Integrate Shape-Memory or Self-Healing Polymers?

Yes, creating truly "smart" coatings. By embedding photothermal graphene into a shape-memory polymer (SMP) matrix, you create a coating that can be remotely activated to change shape. Light absorbed by the graphene heats the surrounding SMP above its transition temperature, triggering a pre-programmed shape change (e.g., opening micro-vents for breathability in a smart textile). Furthermore, graphene can be combined with self-healing polymers. If the coating is scratched, localized heating (from light or an electrical current through the conductive graphene network) can accelerate the healing process of the polymer matrix. This is a key focus of DARPA-funded research into materials for extreme environments.

What Are the Key Performance Metrics and Applications?

Evaluating photothermal graphene coatings requires specific metrics beyond standard coating tests, tied directly to their intended applications.

How is Photothermal Conversion Efficiency Measured and Optimized?

The core metric is Photothermal Conversion Efficiency (η), calculated by measuring the steady-state temperature rise of the coated sample under controlled illumination and accounting for heat losses (convection, conduction, radiation). State-of-the-art coatings now achieve η > 90%. Efficiency is optimized by:

- Maximizing Light Absorption: Using porous or wrinkled graphene structures to reduce reflection.

- Minimizing Thermal Loss: Using underlying insulating layers or aerogel substrates.

- Enhancing Thermal Conduction: Ensuring good percolation of the graphene network within the coating.

Testing standards are still emerging, but methods are often adapted from solar thermal collector testing (ISO 9806).

What Are the Leading Application Sectors?

- Smart Textiles & Apparel: Heated clothing, adaptive insulation, and moisture-warming fabrics for outdoor gear. Masks with photothermal linings can provide facial warming in cold climates.

- Medical & Therapeutic Devices: Patches for photothermal therapy (cancer treatment, pain relief), wound dressings that promote healing through mild heating, and anti-icing coatings for surgical tools.

- Energy & Environment: Solar-driven water purification/desalination coatings, anti-icing/de-icing coatings for wind turbines and aircraft, and coatings for enhanced solar thermal collection.

- Advanced Manufacturing: Coatings for selective soldering or welding in electronics, and for triggering chemical reactions in catalytic systems.

Conclusion

The latest photothermal graphene coating technologies are defined by high-efficiency material forms like optimized rGO and hybrid composites, enabled by scalable and precise application methods like printing and LbL assembly, and evolving toward multifunctional smart systems that integrate thermal storage or shape-changing capabilities. Performance is soaring, with conversion efficiencies now rivaling traditional heating methods. As production costs of graphene continue to fall and formulation science advances, these coatings are poised to move from specialized applications into mainstream products, offering a clean, efficient, and controllable way to generate heat precisely where and when it is needed.

Ready to explore how photothermal graphene coatings can add innovative heating functionality to your products? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss coating development, material sourcing, or integrating this cutting-edge technology into your next-generation designs.