The convergence of advanced biomaterials and precision engineering has given rise to a revolutionary approach to thermal management: silk-microfluidic cooling technologies. These systems leverage the unique properties of silk fibroin protein to create flexible, biocompatible, and highly efficient microfluidic networks for targeted cooling, offering transformative potential for wearables, medical devices, and electronics. For innovators in smart textiles, personal protective equipment, and implantable technologies, understanding these latest developments is crucial for designing next-generation products that manage heat with unprecedented elegance and efficiency.

Silk-microfluidic cooling technologies utilize biocompatible silk fibroin substrates patterned with intricate micro-scale channels through which cooling fluids (often water or saline) are circulated, enabling precise, localized, and active temperature control for skin-contact applications, electronic components, or biological tissues. This approach combines silk's exceptional mechanical flexibility, optical transparency, and tunable degradation with the high heat-transfer efficiency of microfluidics. The latest advancements focus on enhancing fabrication precision, integrating smart flow control, and creating fully biodegradable or resorbable systems.

Research in Science Advances and Nature Communications highlights that optimized silk-microfluidic systems can achieve cooling fluxes exceeding 100 W/cm² with sub-second response times, outperforming many conventional solid heat sinks for irregular surfaces. For applications like cooling vests for athletes, thermal management masks for extreme environments, or postsurgical healing patches, this technology represents a paradigm shift. Let's explore the cutting-edge developments in this field.

What Advanced Fabrication Methods Enable Complex Silk Microfluidics?

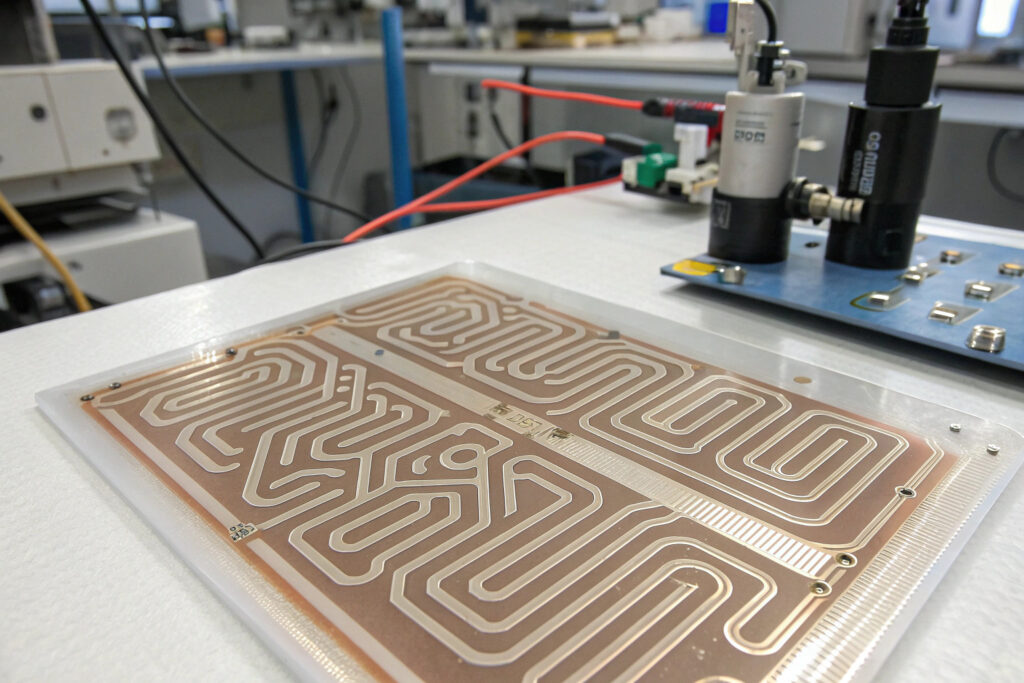

The creation of high-resolution, leak-proof microfluidic channels within silk films or scaffolds is foundational. Traditional soft lithography has evolved to meet the specific demands of protein-based materials.

How Does Micro-Molding and Embossing Work with Silk?

Silk fibroin in its aqueous form can be cast onto micromachined molds made of silicon, SU-8 photoresist, or PDMS.

- Process: The liquid silk solution fills the negative features of the mold. After controlled drying and crystallization (often induced by water vapor or methanol), the solid silk film is demolded, retaining the precise channel structures.

- Advancements: Latest techniques use two-photon polymerization or high-aspect-ratio UV lithography to create molds with more complex 3D channel architectures (e.g., bifurcating networks, vertical interconnects) for improved fluid distribution and heat exchange.

- Resolution: State-of-the-art methods can achieve channel widths down to 5-10 micrometers with high fidelity, allowing for denser cooling networks. Research from the Tufts University Silklab shows that such precision enables mimicking the efficiency of biological vascular networks.

Can Silk Microfluidics Be Directly Printed or Written?

Yes, additive manufacturing is revolutionizing the field.

- Inkjet Printing of Silk "Inks": Functionalized silk solutions can be printed directly onto substrates to form channel walls or sacrificial templates. This allows for on-demand, customizable patterning without the need for a physical mold.

- Embedded 3D Printing: A technique where a silk-based ink is extruded within a supporting gel bath. This allows for the freeform creation of suspended microfluidic channels that would collapse using traditional methods, enabling truly 3D cooling networks.

- Laser Direct Writing: Using focused lasers to selectively ablate or crosslink silk films, creating channels or modifying local permeability to guide fluid flow.

These direct-write approaches, highlighted in Advanced Materials Technologies, are key for prototyping and creating patient-specific devices.

What Smart Fluidic Control and Functionalization Methods Exist?

The cooling performance is determined not just by the channel geometry, but by the properties of the fluid and the dynamic control of its flow.

How are Phase-Change Fluids (PCFs) and Nanofluids Enhancing Cooling?

Moving beyond simple water, advanced coolants are being integrated:

- Silk-Encapsulated Phase-Change Materials (PCMs): Microcapsules of paraffin or salt hydrates can be suspended in the circulating fluid or embedded in the silk matrix itself. As they absorb heat and melt, they provide a high latent heat buffer, stabilizing temperature for extended periods. The silk shell ensures biocompatibility and prevents leakage.

- Nanofluids: Suspensions of high-thermal-conductivity nanoparticles (e.g., graphene, boron nitride) in the base fluid. These can significantly enhance the thermal conductivity of the coolant. The challenge is preventing particle aggregation and ensuring the silk channels are not abraded; functionalizing nanoparticles with compatible coatings is an active area of research.

The synergy of silk's interface and advanced coolants is pushing the limits of heat transfer density.

Can Flow Be Autonomously Regulated?

Inspired by perspiration, the latest systems incorporate responsive elements:

- Temperature-Responsive Hydrogel Valves: Sections of the microchannel can be lined with a polymer like PNIPAM that swells and constricts the channel at lower temperatures, and shrinks to open it at higher temperatures. This creates passive, localized feedback without any electronics.

- Shape-Memory Silk Actuators: By programming the silk's crystalline structure, specific regions can be designed to deform (e.g., pinch a channel) in response to a thermal trigger, providing built-in flow control.

These passive regulatory mechanisms are crucial for creating self-contained, energy-free cooling systems for wearables.

What Are the Key Integration Strategies for Wearable and Medical Use?

Translating laboratory prototypes into functional devices requires innovative integration approaches that maintain performance under real-world conditions.

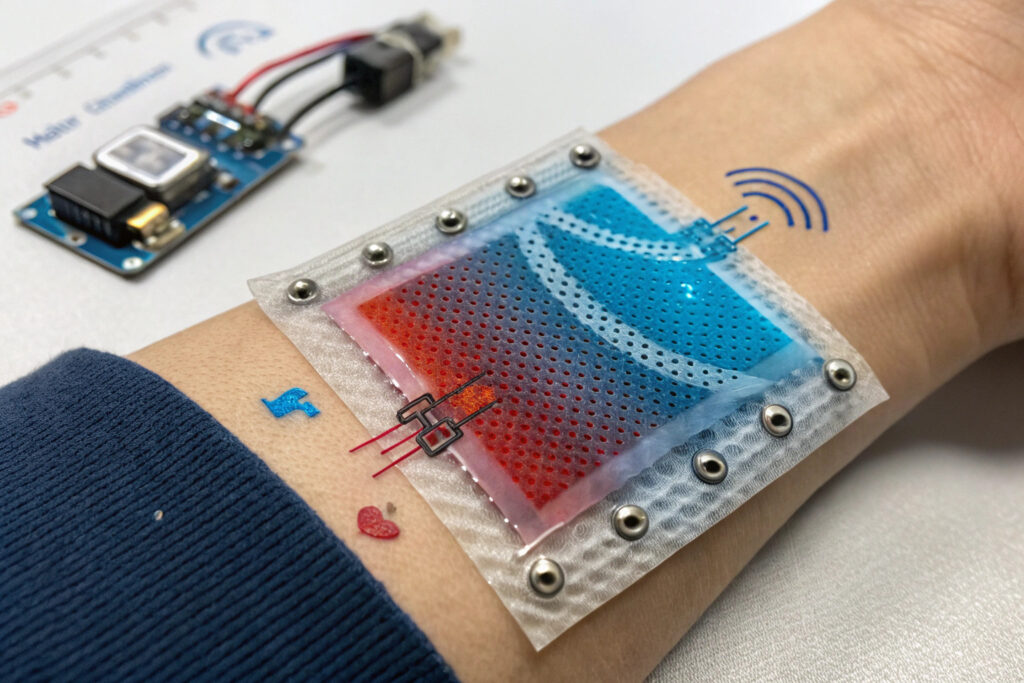

How Are Systems Integrated with Electronics or Skin?

- Heterogeneous Integration: For cooling electronics (e.g., a CPU in a wearable computer), the silk-microfluidic layer is laminated onto the chip package using a thermally conductive adhesive. Silk's smooth surface enables excellent conformal contact with uneven surfaces, reducing thermal interface resistance.

- Wearable Textile Integration: Silk films can be bonded to or woven into textiles. Inlet and outlet ports are connected to flexible tubing routed to a small, wearable pump and reservoir pack (e.g., worn on a belt). The latest work focuses on minimizing the "plumbing" by creating all-silk, capillary-driven systems that require no external pump for low-power cooling.

- Bio-Integration for Medical Patches: For cooling skin (e.g., to treat burns or reduce inflammation), the silk side in contact with skin can be functionalized with bioactive molecules to promote healing. The entire system can be designed to be bioresorbable—after a healing period, the silk degrades and the harmless coolant is metabolized or absorbed, eliminating the need for a second surgery to remove the device.

How are Power and Pumping Managed in Wearables?

The need for a pump is the main barrier to widespread adoption in consumer wearables. Cutting-edge solutions include:

- Electrohydrodynamic (EHD) or Electroosmotic Pumps: These solid-state pumps can be miniaturized directly onto the silk substrate, moving fluid silently with very low power using high voltage but minimal current. They have no moving parts, enhancing reliability.

- Energy Harvesting Integration: Pairing the system with a flexible piezoelectric harvester that converts body movement into the electrical energy needed to run a micropump.

The goal is a self-sustaining or minimally intrusive active cooling system.

What Are the Performance Benchmarks and Emerging Applications?

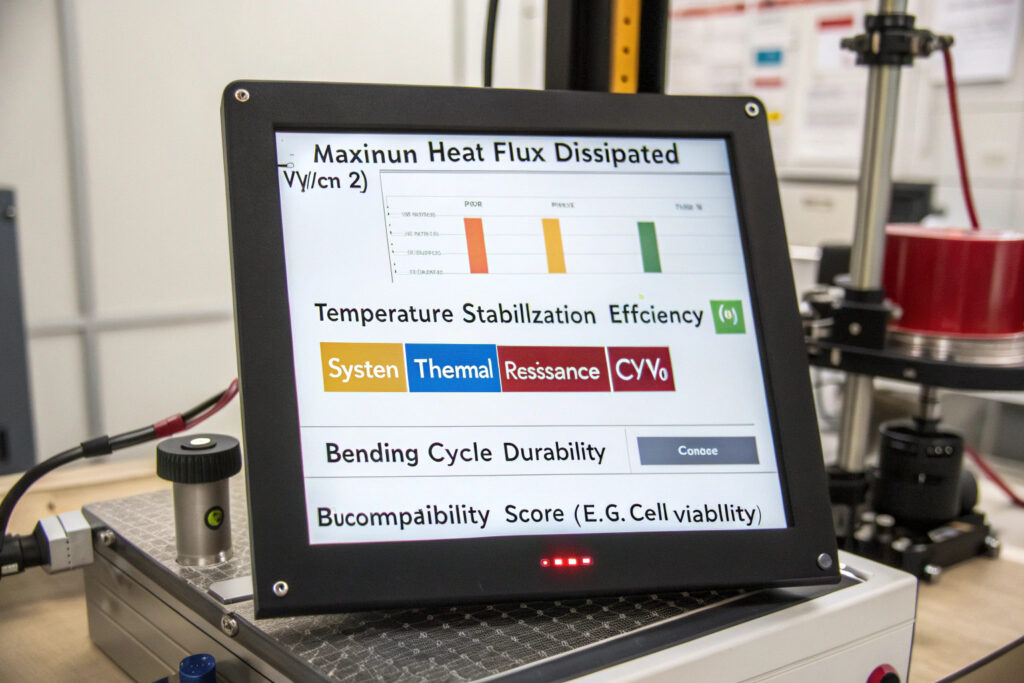

Evaluating these systems requires metrics beyond standard cooling, considering their unique material properties and intended environments.

How is Cooling Performance Quantified?

- Heat Flux Dissipation: The maximum power per unit area the system can remove while maintaining the target temperature. Advanced silk-microfluidic systems now report values >50 W/cm² for targeted cooling, rivaling metal heat sinks for high-power electronics.

- Temperature Uniformity: The spatial variation across the cooled surface. Vascular-inspired channel designs (like fractal patterns) excel here.

- Response Time: How quickly the system reacts to a sudden heat load. Microfluidics offer sub-second response due to the small thermal mass of the fluid in the channels.

- Coefficient of Performance (COP): For active systems, the ratio of cooling power to electrical input power. High COP is critical for battery-operated wearables.

What are the Frontier Applications?

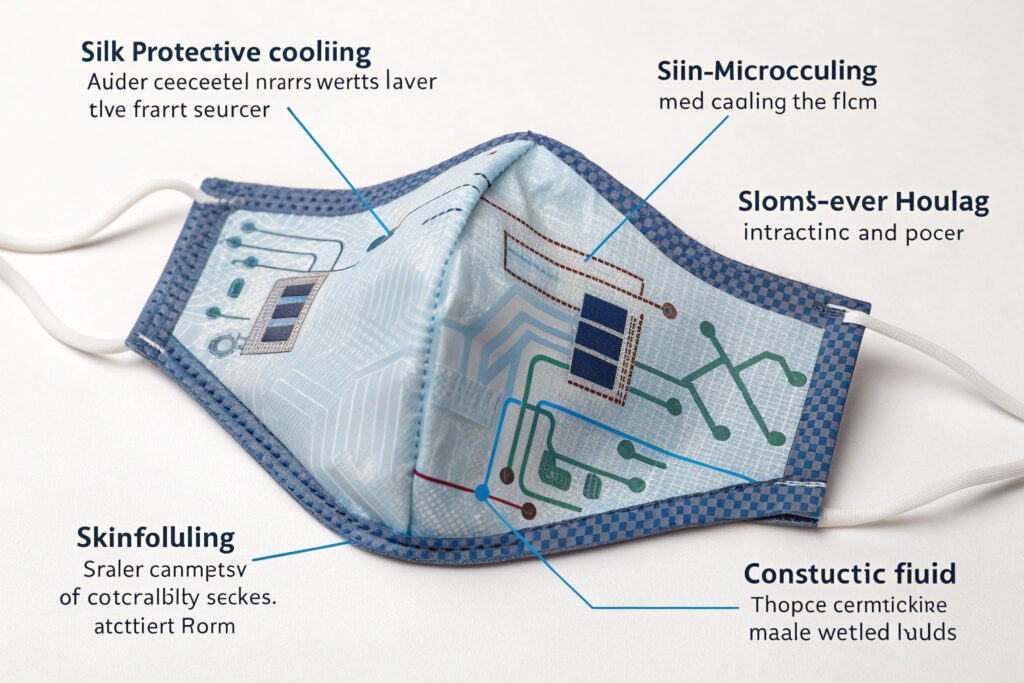

- Proactive Thermal Management Masks (PTMM): Masks for firefighters, steelworkers, or in pandemic PPE that actively cool the inhaled air and the facial skin, preventing heat stress and extending safe work duration. Silk's biocompatibility makes it ideal for prolonged skin contact.

- Post-Operative and Burn Care: Bioresorbable cooling patches that precisely manage tissue temperature to reduce swelling, pain, and metabolic demand, then harmlessly dissolve.

- High-Density Flexible Electronics: Cooling the next generation of foldable displays and wearable computers where traditional metal heat spreaders are too rigid.

- Sports Performance Wear: Lightweight, form-fitting cooling garments that enhance athlete endurance and recovery.

Conclusion

The latest silk-microfluidic cooling technologies represent a powerful fusion of natural material elegance and engineering precision. They are defined by high-resolution, often 3D-printed vascular networks, the integration of smart coolants and passive flow control, and strategies for seamless, sometimes resorbable, integration into wearables and medical devices. While challenges in long-term durability under dynamic mechanical stress and miniaturization of pumping systems remain, the trajectory is clear: toward personalized, adaptive, and biologically harmonious thermal management systems. As fabrication costs drop and performance scales, we can expect these systems to move from high-value medical and military applications into mainstream consumer products, redefining our ability to manage heat at the human-machine interface.

Ready to explore how silk-microfluidic cooling can solve thermal challenges in your next wearable or medical product? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss potential applications, prototyping pathways, and sourcing strategies for this cutting-edge thermal technology.