Custom dye matching represents one of the most sought-after yet challenging aspects of fashion mask production, balancing the desire for unique brand colors against the practical realities of textile manufacturing economics. The minimum order quantities for custom dye-matched masks vary significantly based on color complexity, fabric type, and the dyeing methodology employed.

MOQs for custom dye-matched fashion face masks typically range from 1,000-5,000 pieces per color, with basic custom colors starting at 1,000-2,000 pieces and complex or multiple-color designs requiring 3,000-5,000 pieces. These thresholds reflect the substantial setup costs, laboratory work, and material minimums involved in creating unique, consistent dye lots.

The process of custom dye matching involves far more than simply adding color to fabric—it requires color chemistry expertise, laboratory testing, production trials, and quality verification to ensure color consistency across production runs. Understanding what drives these MOQs helps brands make informed decisions about their color strategy and product development timeline.

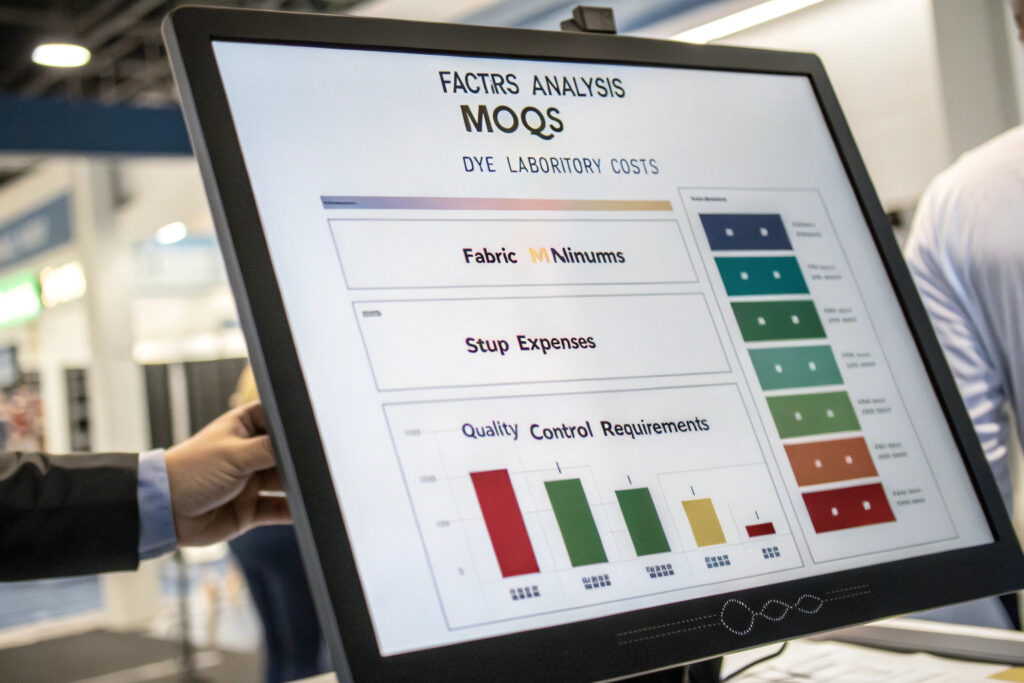

What Factors Determine Custom Dye MOQ Requirements?

Multiple technical and economic factors influence where manufacturers set MOQ thresholds for custom dye work.

How do dye house minimums impact MOQs?

Dye bath minimums typically require 50-100kg of fabric per color, which translates to 2,000-4,000 masks depending on fabric weight and mask size. Dye houses establish these minimums because the same labor, equipment, and chemical resources are required regardless of batch size. Our partner dye houses have minimums starting at 60kg, which supports approximately 2,500-3,000 standard adult masks.

Why does color complexity affect quantity requirements?

Complex color development involving multiple dye combinations or special effects requires more laboratory work and production testing, increasing the development costs that must be amortized across the order. A basic solid color might require 3-5 lab dip iterations, while a complex fashion color with specific undertones could need 8-12 iterations. This additional development typically increases the MOQ by 30-50% for complex colors.

What Are the Different Tiers of Custom Dye MOQs?

Custom dye MOQs typically fall into distinct tiers based on color complexity and customization level.

What can you achieve with 1,000-2,000 piece MOQs?

At this entry level, manufacturers typically work with existing dye formulas that require minor adjustments rather than completely new color development. This tier works for brands wanting specific Pantone matches that are similar to colors the dye house already produces regularly. Our basic custom dye program at 1,500 pieces focuses on adjusting existing formulas with 3-5 lab dip iterations.

What becomes possible at 3,000-5,000 pieces?

Higher MOQs enable true custom color development including completely new formulas, specialized dyeing techniques, and complex color effects. This volume supports the development work needed for fashion-forward colors with specific undertones or multi-tonal effects. Our comprehensive custom dye program at 3,500+ pieces includes unlimited lab dips and custom formula development.

How Can You Reduce Custom Dye MOQs?

Strategic approaches can sometimes lower the effective MOQ requirements for custom color development.

How does color family development help?

Developing coordinated color families across multiple products allows dye development costs to be shared, effectively reducing the per-color MOQ. By developing 3-5 colors in the same dye session using related formulas, manufacturers can often reduce individual color MOQs by 20-30%. Our color family approach has enabled clients to achieve custom colors at 1,200-1,800 pieces rather than the standard 2,000+ minimum.

What about strategic fabric selection?

Choosing fabrics with better dye affinity can reduce the laboratory work required to achieve color matches, potentially lowering MOQs. Natural fibers like cotton and bamboo typically dye more predictably than synthetic blends, requiring fewer lab dip iterations. Our fabric recommendation system identifies materials that balance dye performance with other functional requirements.

What Are the Cost Implications Beyond MOQs?

Understanding the full cost structure of custom dye work helps in evaluating the total investment required.

How do development costs factor into pricing?

Laboratory and development fees typically add $400-800 per color to initial costs, covering lab dips, color matching, and testing. These are usually one-time fees amortized across the first production run. Additionally, custom-dyed fabric typically carries a 15-30% premium over stock colors. Our custom dye pricing includes transparent breakdowns of these cost components.

What minimum charges apply regardless of quantity?

Most dye houses implement minimum development charges of $600-1,200 that apply even for smaller quantities, making very low MOQs economically impractical. These minimums cover the fixed costs of laboratory work, regardless of how much fabric is ultimately dyed. Our pricing structure clearly identifies these minimum charges to prevent surprises.

What Timeline Considerations Should You Factor In?

Custom dye development extends production timelines significantly, requiring advance planning.

How long does custom color development take?

The custom dye development process typically adds 3-5 weeks to standard production timelines, including laboratory work, sample approval, and production dyeing. Complex colors requiring multiple iterations can extend this to 6-8 weeks. Our standard custom dye timeline is 4 weeks from color brief to approved lab dip, plus production scheduling.

What approval processes impact timing?

Lab dip approval cycles require careful evaluation under different lighting conditions and often involve multiple iterations. Each approval cycle typically takes 5-7 days, with most projects requiring 2-4 cycles. Our digital lab dip process has reduced approval cycles to 3-4 days by providing detailed color measurement data alongside physical samples.

What Quality Assurance Measures Ensure Color Consistency?

Maintaining color consistency across production runs requires specific quality controls.

How is color consistency verified?

Spectrophotometer measurement with Delta E tolerance standards ensures colors match approved standards within acceptable visual ranges. The industry standard is Delta E ≤2.0 for acceptable matches, with premium manufacturers achieving ≤1.5. Our color quality standard is Delta E ≤1.2, ensuring virtually indistinguishable color consistency.

What testing prevents future color issues?

Colorfastness testing including wash fastness, rub fastness, and lightfastness verification ensures colors maintain their appearance through use and cleaning. This is particularly important for fashion masks where color deterioration affects perceived quality. Our standard testing protocol includes 5-wash cycle testing and 40-hour lightfastness evaluation.

Conclusion

MOQs for custom dye-matched fashion face masks typically range from 1,000-5,000 pieces per color, reflecting the substantial technical work and economic considerations involved in custom color development. While these thresholds represent significant commitments, strategic approaches like color family development, fabric selection, and production planning can optimize the investment. The resulting unique brand colors often justify the premium through enhanced market positioning and brand recognition.

The decision to pursue custom dye work should balance the brand value of unique colors against the practical considerations of development time, cost, and quantity requirements. For established brands with clear color identities, custom dyes often represent a worthwhile investment that strengthens brand recognition.

Ready to explore custom dye options for your fashion face masks? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our custom dye capabilities and receive a detailed proposal based on your specific color requirements. We'll help you navigate the MOQ considerations while achieving your vision for unique brand colors.