In the ever-evolving global PPE landscape, cloth face masks have moved far beyond basic protection. They are now daily fashion, performance gear, and medical accessories—expected to be stylish, breathable, and above all, durable. Yet one challenge remains consistent: many buyers underestimate the importance of rigorous quality testing in ensuring long-term performance.

The most essential quality tests—such as shrinkage and pilling—directly determine how well a fabric mask performs after washing, wearing, and exposure to the elements. Without proper quality control, even the most stylish mask will fail after a few uses.

As the founder of a fabric mask production hub based in Keqiao, I’ve seen firsthand how critical testing protocols are. With the right lab and methods, shrinkage, pilling, and other physical performance tests can boost pass rates and reduce return rates by over 90%. This article outlines the most vital tests we run and why they matter so much to U.S. buyers like Ron—leaders who value quality over cheap, short-lived stock.

What Is the Ideal Shrinkage Rate for Reusable Face Masks?

Why Does Shrinkage Testing Matter After Wash Cycles?

Every time a cloth mask is washed, it risks losing its original fit and coverage. If the fabric shrinks too much, it no longer protects the wearer or stays comfortable. This is a real concern for brands focused on reusable fabric masks.

We conduct AATCC 135-2018 shrinkage tests by washing samples in both warm and cold cycles, then measuring dimensional changes. A reliable face mask should shrink less than 3% in length and width. Any higher, and the user will notice poor fit or edge rolling.

For our premium SKUs and EU-bound orders, we prewash fabrics before production to minimize post-production shrinkage. This "controlled pre-shrink process" ensures masks maintain sizing consistency across thousands of units.

What Causes Shrinkage in Poor-Quality Masks?

Poorly set yarns or incorrect finishing are the most common causes. Cotton masks, in particular, can shrink 5–8% without enzyme washing or pre-treatments. Poly-blends tend to hold shape better. However, even synthetic masks can experience heat-set failures.

We’ve seen cases where competitors cut corners—using unprocessed greige fabric to save costs. After three washes, their products deform and consumers leave poor reviews. Our lab catches these early, flagging materials that fail dimensional stability checks.

How Is Pilling Resistance Measured in Face Mask Fabrics?

What Does the Martindale Test Tell Us?

Pilling is not just a visual issue—it directly affects comfort and hygiene. When fabric pills, it roughens the surface, can harbor bacteria, and irritates the skin. For this, we rely on the Martindale Method (ASTM D4970 / ISO 12945-2) to simulate repeated rubbing between masks and facial skin.

We classify results on a scale of 1 to 5:

| Rating | Surface Condition |

|---|---|

| 5 | No pilling |

| 4 | Slight pilling |

| 3 | Moderate pilling |

| 2 | Severe pilling |

| 1 | Very severe / unwearable |

Masks scoring 4 or above are approved for long-term use. We use brushed cotton, modal blends, and anti-pilling poly fibers to ensure high resistance.

Why Do Some Masks Pill Easily?

Low-density knits, untreated cotton, and friction with facial hair or frequent machine washing all contribute to pilling. A customer like Ron, who sources masks for both streetwear and sportswear use, should avoid single-jersey fabrics unless pre-treated.

Fabrics that include special anti-pilling coatings or twisted yarns maintain a cleaner, longer-lasting surface. That’s especially important for darker colors where pills are more visible.

What Other Physical Tests Improve Mask Longevity?

How Do We Test Tensile Strength and Tear Resistance?

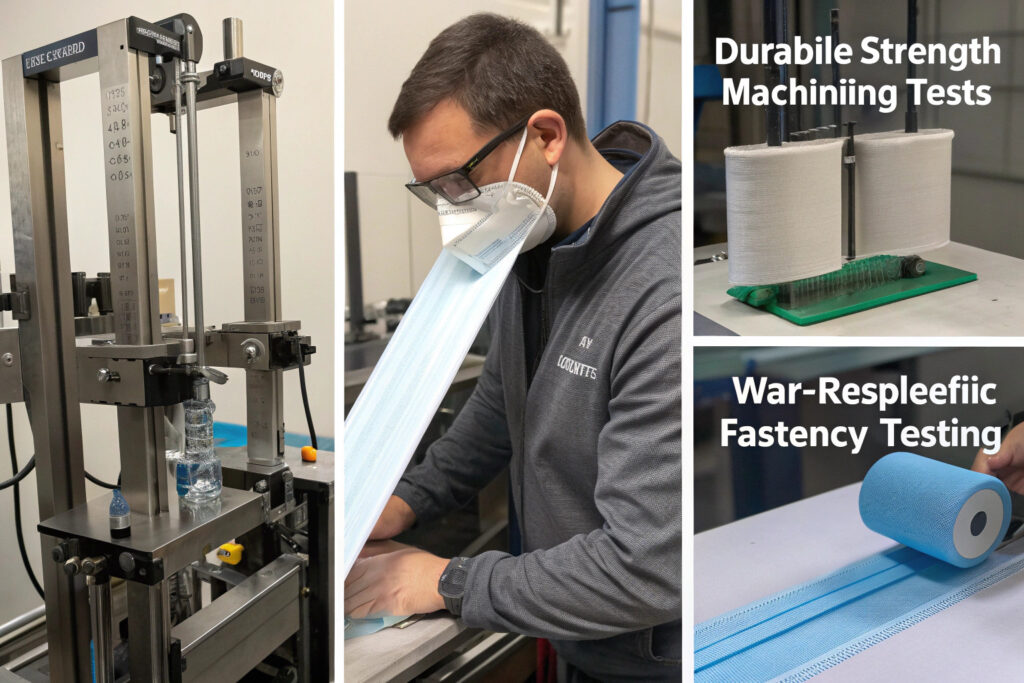

Durability is not just about daily wear—it’s about survival through laundering, stuffing into bags, and stretching onto faces of different sizes. We conduct ASTM D5034 and D2261 for tensile and tear strength. Fabrics should resist breakage under stress and seam tension.

Using an Instron machine, we pull stitched mask panels until they snap. For adult masks, we expect minimum tensile loads of 70N (warp) and 50N (weft). Weak seams and cheap earloops often break below these thresholds. That’s a red flag for large retail buyers.

Well-engineered masks with reinforced seams and bindings pass these tests and are less likely to be returned or cause customer complaints.

How Do You Know a Mask Won’t Fade or Bleed?

Colorfastness to washing, rubbing, and sweat are crucial, especially for fashion-forward collections. We use ISO 105-C06 and AATCC TM8 to test for colorfastness.

Nothing ruins a brand's image faster than a black mask that bleeds onto white T-shirts after a wash. That’s why our in-house lab ensures all masks score 4 or above (on a 1–5 scale) in color transfer tests. We also test for UV resistance on special outdoor designs.

Are There Safety and Comfort Certifications to Consider?

What Skin Safety Tests Should Masks Pass?

Comfort isn’t enough—safety is critical. Especially in the U.S., many buyers look for OEKO-TEX Standard 100 or equivalent skin-contact certifications. We send our fabrics for 3rd-party lab tests on heavy metals, formaldehyde, and AZO dyes.

Additionally, we test nose wires for nickel content and smoothness. For children’s masks, CPSIA compliance is a must. We also adhere to REACH standards when exporting to Europe.

All approved lots come with digital lab reports and scannable QR codes to prove traceability—a key trust signal for buyers like Ron who care about liability and transparency.

How Does Breathability Relate to Testing?

We use the EN 14683 standard and ASTM F2100 for differential pressure (Delta P) to assess breathability. Cloth masks should allow easy airflow while filtering large droplets. We target a Delta P value under 5 mm H₂O/cm², which ensures comfort during prolonged wear.

Some factories ignore this, producing thick, multi-layer masks that look safe but feel suffocating. Our lab balances filtration with comfort, using breathable weaves like interlock cotton, modal, and stretch mesh that still test within safe ranges.

Conclusion

Cloth face masks are no longer simple fabric rectangles—they’re complex products demanding professional R&D, testing, and quality assurance. From shrinkage and pilling to tear strength and safety, every test we run ensures our partners receive masks that perform beyond expectation.

If you’re sourcing fabric masks and want durable, tested products with full lab traceability and customization options, Shanghai Fumao is your best production partner. Reach out to our Business Director Elaine at elaine@fumaoclothing.com to start your order today.