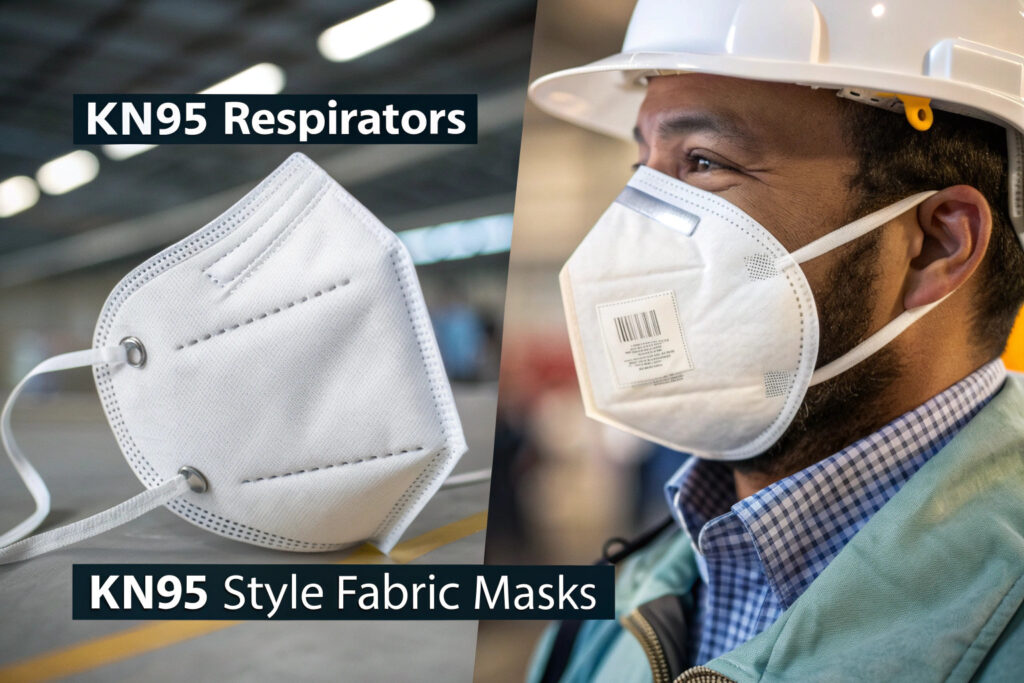

The market for KN95-style fabric masks has grown rapidly, but with this growth comes confusion about what standards actually apply and what protection these products truly offer. Consumers see "KN95-style" claims but often don't understand these are fashion masks, not certified respiratory protection. Understanding the applicable standards is crucial for both manufacturers seeking compliance and brands making accurate marketing claims.

KN95-style fabric masks with PM2.5 filters must comply with textile safety standards for the mask materials and filter media, not the rigorous KN95 respiratory protection standard, unless they have undergone specific certification testing. The key standards include OEKO-TEX® for textile safety, ASTM F3502 for barrier face coverings, and regional regulations for filter media, but these differ significantly from the GB 2626-2019 standard that governs authentic KN95 respirators.

The distinction between "KN95-style" and certified KN95 respirators represents a crucial regulatory and safety boundary. Let's examine what standards actually apply to these popular hybrid products and how to ensure compliance while making accurate claims.

What Standards Govern the Fabric Mask Components?

The fabric portions of these masks fall under textile product regulations rather than respiratory protection standards, creating a different compliance landscape.

Why do textile safety standards apply to the mask shell?

The fabric mask shell is considered a textile product, requiring compliance with general product safety regulations and specific textile standards. OEKO-TEX® Standard 100 certification verifies the absence of harmful substances in textiles, which is particularly important for products worn against the skin for extended periods. Additionally, depending on the market, CPSIA (Consumer Product Safety Improvement Act) compliance may be required for lead and phthalate content, especially for masks marketed toward children. These certifications ensure basic material safety but don't address filtration performance.

What about breathability and barrier performance?

The ASTM F3502-21 standard for barrier face coverings provides a more relevant framework for evaluating fabric mask performance, measuring both filtration efficiency (20-25% minimum for Level 1) and breathability (≤15 mm H₂O pressure difference for Level 1). While not legally mandatory in most markets, this standard represents the most appropriate existing framework for evaluating the protective qualities of fabric masks. Our testing shows that well-constructed KN95-style fabric masks typically achieve 25-40% filtration efficiency without filters and 60-85% with quality PM2.5 filter inserts.

What Regulations Apply to PM2.5 Filter Inserts?

The filter component represents the most technically complex element, with varying regulatory approaches across different markets.

How are PM2.5 filters regulated as components?

PM2.5 filter inserts typically fall into a regulatory gray area between textile products and medical devices. In the United States, unless specific medical claims are made, they're generally regulated as consumer products requiring general safety compliance. The filter media should meet relevant material safety standards, while the filtration claims should be supported by testing to recognized methodologies. However, unlike NIOSH-approved respirator filters, there's no specific certification program for consumer PM2.5 filter inserts, creating potential for misleading claims.

What testing validates filter performance?

Reputable manufacturers test filter media using recognized methodologies, though these differ from the sodium chloride aerosol test required for KN95 certification. Common approaches include TSI 3160 testing or similar methods using latex spheres or salt particles in the 0.3 micron range. The "PM2.5" designation refers to the particle size the filter targets (2.5 microns), not a specific performance standard. Our filter testing follows a comprehensive protocol that includes initial efficiency, loading characteristics, and breathability to ensure realistic performance claims.

How Do Regional Regulations Differ?

The regulatory landscape varies significantly across different markets, requiring tailored compliance approaches for international distribution.

What applies in the United States market?

In the U.S., the FDA regulates medical masks, while the Consumer Product Safety Commission oversees general consumer masks unless specific medical claims are made. The FTC monitors advertising claims for accuracy, particularly regarding protection levels. For KN95-style fabric masks, the most relevant framework is the ASTM F3502 standard for barrier face coverings, though compliance is voluntary unless specified by retailers or specific jurisdictions. Additionally, California's Proposition 65 requires warnings if products contain chemicals known to cause cancer or reproductive harm.

What about European and other international markets?

The European Union applies the General Product Safety Directive along with REACH regulations restricting hazardous chemicals in consumer products. The CE marking indicates conformity with health and safety standards, though specific performance standards for fabric masks are still developing. In Asian markets, regulations vary widely, with China's GB standards applying to domestic products but not necessarily to exports. Our compliance team maintains updated requirements for over 50 countries, with particular attention to evolving regulations in the EU and North American markets.

What Labeling and Marketing Claims Are Permissible?

The claims made about KN95-style fabric masks significantly impact their regulatory classification and compliance requirements.

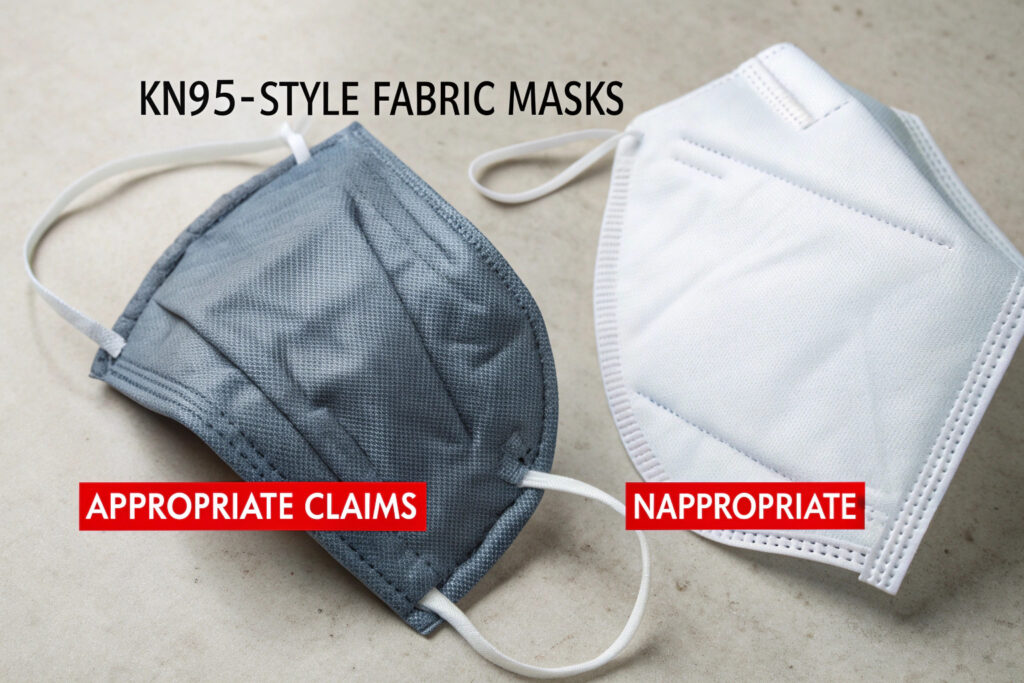

What claims trigger higher regulatory categories?

Using terms like "respirator," "protection," or making specific filtration percentage claims without proper testing can trigger medical device or PPE classification in many jurisdictions. Similarly, comparing performance to certified respirators like KN95, N95, or FFP2 standards may draw regulatory scrutiny unless the products have actually been tested to those standards. We recommend clients use descriptive language about features rather than protection claims, focusing on comfort, style, and general use rather than medical or occupational applications.

How should performance be accurately communicated?

Transparent communication should distinguish between the mask system's performance and the filter's capabilities, noting that real-world effectiveness depends on fit, fabric, and filter combination. Marketing should clearly state that these are not certified respirators and are intended for general public use rather than healthcare settings. Our clients have successfully positioned these products as fashion accessories with added filtration features, avoiding regulatory issues while meeting consumer demand for both style and function.

What Due Diligence Ensures Compliance?

Manufacturers and brands share responsibility for ensuring their KN95-style fabric masks meet applicable standards and make accurate claims.

What documentation should manufacturers provide?

Reputable manufacturers should provide comprehensive testing documentation including material safety certificates (OEKO-TEX®, CPSIA), filtration performance data, and breathability test results. Additionally, they should maintain a technical file documenting compliance with all applicable regulations in target markets. Our documentation package includes test reports from internationally accredited laboratories, material safety data sheets, and detailed specifications supporting all performance claims.

How can brands verify compliance independently?

Brands should conduct supplier audits either directly or through third parties to verify manufacturing practices and quality control systems. Additionally, periodic independent testing of production samples provides ongoing verification of performance claims. We encourage clients to conduct random testing of shipments to ensure consistent quality and have established transparent processes for client-requested independent verification at accredited laboratories.

Conclusion

KN95-style fabric masks with PM2.5 filters occupy a complex regulatory position between general textiles and respiratory protection. Compliance requires understanding and applying the appropriate textile safety standards, accurately representing filter performance without making medical claims, and maintaining proper documentation for all target markets. The key distinction remains that these are fashion masks with filtration features, not certified respiratory protection, and should be marketed accordingly.

Ready to navigate the complex regulatory landscape for KN95-style fabric masks? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our compliant manufacturing approach and comprehensive testing protocols. We'll help you develop products that meet all applicable standards while making accurate marketing claims.