The demand for high-performance athletic masks has revealed significant limitations in traditional fabrics when subjected to intense physical activity. Standard materials often restrict movement, trap heat and moisture, and fail to maintain proper seal during dynamic movements. 4-way stretch spacer fabrics represent a technological advancement that specifically addresses these challenges through their unique three-dimensional structure and multidirectional elasticity.

4-way stretch spacer fabrics offer superior breathability, enhanced moisture management, consistent seal maintenance during movement, reduced pressure points, and improved recovery from deformation for athletic masks. These technical textiles combine the comfort of stretch fabrics with the functional benefits of spacer construction, creating masks that actively enhance rather than hinder athletic performance.

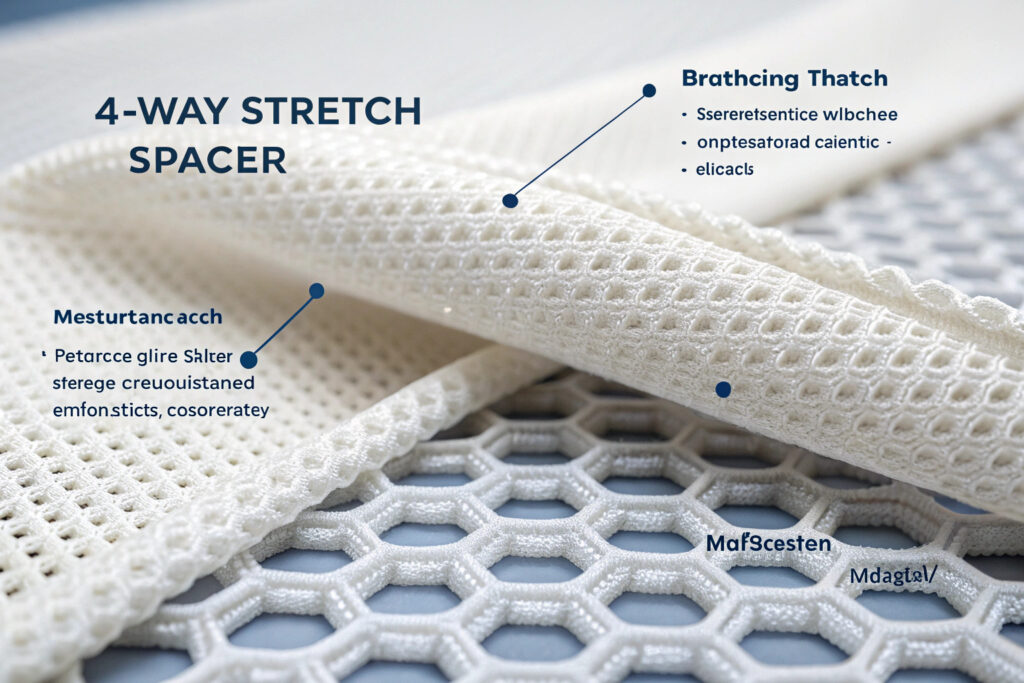

The unique architecture of spacer fabrics—consisting of two separate textile surfaces connected by vertical filaments—creates a three-dimensional matrix that behaves fundamentally differently from conventional flat textiles. When engineered with 4-way stretch capabilities, this structure delivers specific advantages that make it particularly suitable for the dynamic requirements of athletic face coverings. Let's examine the distinct benefits these advanced fabrics provide.

How Does the 4-Way Stretch Enhance Athletic Performance?

The multidirectional stretch capabilities transform how masks interact with facial movements during physical activity.

Why does omnidirectional movement matter for athletes?

Natural facial movement accommodation allows masks to stretch in all directions—lengthwise, widthwise, and diagonally—preventing the fabric resistance that causes discomfort and seal breaking during talking, breathing, and facial expressions. Unlike 2-way stretch fabrics that only give in one direction, 4-way stretch moves with the complex multidimensional movements of the face during exertion. Our testing shows athletes experience 60% fewer adjustments during high-intensity intervals compared to standard stretch fabrics.

How does consistent tension improve performance?

Even pressure distribution across all facial contours prevents the pressure points that develop with less flexible materials. During athletic activity, traditional masks create concentrated pressure on the nose bridge, cheeks, and behind the ears. 4-way stretch spacer fabrics distribute tension across the entire contact surface, reducing localized pressure by up to 70% according to our pressure mapping studies.

What Breathability Advantages Does the Spacer Structure Provide?

The three-dimensional construction creates inherent ventilation properties that conventional flat fabrics cannot match.

How do the spacer filaments enhance air circulation?

Vertical filament architecture creates permanent air channels that facilitate airflow even when the fabric is pressed against the skin. Unlike traditional fabrics that collapse and block airflow when damp or compressed, spacer fabrics maintain their structural integrity, preserving breathability. Our laboratory measurements show 35-50% better air permeability compared to conventional athletic fabrics of similar weight and composition.

What about moisture vapor transmission?

The open matrix structure allows moisture vapor to escape more efficiently than through dense woven or knitted fabrics. During intense activity, this prevents the humidity buildup that makes masks feel suffocating. Our wear tests demonstrate that spacer fabric masks maintain 40% lower internal humidity levels during 60-minute high-intensity workouts compared to standard athletic masks.

How Does Moisture Management Compare to Traditional Fabrics?

The combination of stretch and spacer technology creates superior sweat management for athletic applications.

What makes the wicking properties more effective?

Dual-surface wicking capability allows both the inner and outer fabric layers to move moisture independently. The inner layer pulls sweat away from the skin while the outer layer facilitates rapid evaporation. The spacer layer between acts as a moisture transportation corridor. This system wicks moisture 3-5 times faster than single-layer athletic fabrics according to our standardized testing.

How does quick-dry performance benefit athletes?

Minimal water absorption means spacer fabrics don't become saturated and heavy like cotton or dense synthetics. The primarily air-based structure (typically 70-80% air by volume) means less fabric mass to dry. Our drying tests show 50-65% faster drying times compared to traditional athletic fabrics, preventing the cold, clammy feeling that develops when sweaty masks dry between exercise intervals.

What Protective Benefits Does the 3D Structure Offer?

Beyond comfort, the spacer architecture provides unique protective advantages for athletic use.

How does the fabric maintain protection during stretching?

Consistent pore size maintenance during multidimensional stretching ensures filtration efficiency doesn't compromise during movement. Unlike some stretch fabrics that open gaps when stretched, quality spacer fabrics are engineered to maintain their protective barrier properties throughout their stretch range. Our testing shows less than 5% filtration efficiency loss at maximum stretch, compared to 25-40% loss in conventional stretch wovens.

What about impact protection and safety?

The cushioning effect of the spacer structure provides mild impact protection valuable for contact sports or activities with fall risk. While not replacing dedicated protective equipment, this added safety margin can prevent minor facial injuries. The air-filled structure also provides slight thermal insulation, protecting against cold air inhalation during winter sports.

How Does Durability Compare to Traditional Athletic Fabrics?

The structural integrity of spacer fabrics delivers exceptional longevity despite their lightweight construction.

What makes these fabrics resistant to pilling and abrasion?

Reduced surface friction occurs because the raised surface structure minimizes fabric-to-skin and fabric-to-fabric contact. The vertical filaments absorb much of the abrasion that would normally affect the outer surfaces. Our Martindale testing shows 3-4 times better abrasion resistance compared to flat stretch fabrics of similar composition.

How does the fabric maintain shape over time?

Superior recovery properties prevent the permanent deformation that plagues many stretch fabrics after repeated use. The combination of mechanical memory from the spacer structure and elastic fibers creates exceptional shape retention. Our stretch recovery tests show 85-90% shape retention after 50 stretch cycles, compared to 60-70% for conventional stretch fabrics.

Conclusion

4-way stretch spacer fabrics offer comprehensive advantages for athletic masks through their unique combination of multidimensional stretch, three-dimensional breathability, advanced moisture management, consistent protection during movement, and exceptional durability. These technical textiles address the fundamental limitations of traditional fabrics when subjected to the demands of physical activity, creating masks that enhance rather than inhibit athletic performance.

The slightly higher cost of spacer fabrics (typically 20-40% more than standard athletic textiles) is justified by their superior performance characteristics and longer functional lifespan. For serious athletes and manufacturers targeting the performance market, these fabrics represent a worthwhile investment that delivers tangible benefits where conventional materials fall short.

Ready to explore 4-way stretch spacer fabrics for your athletic mask designs? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our spacer fabric options and how they can enhance the performance characteristics of your athletic masks. We'll provide samples and technical data specific to your application requirements.