The evolution of fabric masks is entering an exciting phase with the integration of smart textile technologies that actively regulate temperature rather than merely providing a passive barrier. These innovations transform masks from simple protective gear into sophisticated wearable technology that enhances comfort, particularly in extreme temperatures or during physical activity. The emerging technologies address the fundamental discomfort of mask wear—heat buildup and moisture accumulation—through advanced material science and responsive textile engineering.

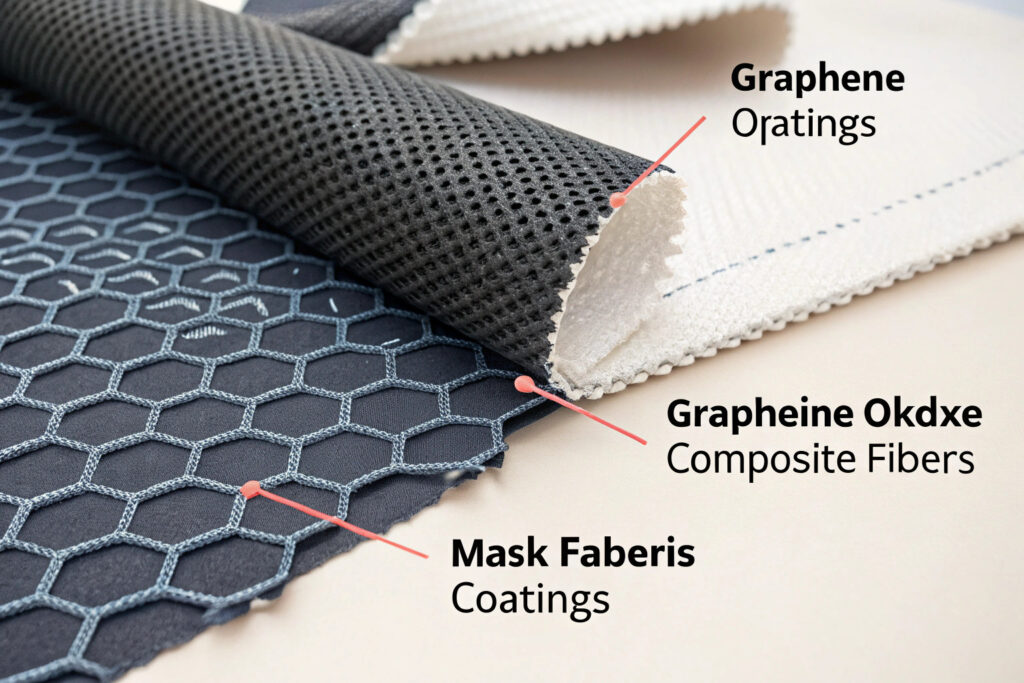

Emerging smart fabric technologies for temperature-regulating masks include phase-change materials (PCMs), thermoregulatory coatings, graphene-enhanced textiles, moisture-activated cooling fabrics, and bio-inspired adaptive materials that respond to body heat and environmental conditions. These technologies create microclimates that maintain optimal temperature ranges, significantly improving wearer comfort and compliance, especially in challenging thermal environments.

The most advanced temperature-regulating technologies work dynamically, absorbing excess heat when the wearer is active or in warm environments and releasing stored heat when temperatures drop. This active regulation represents a significant advancement over traditional materials that simply provide insulation or breathability. Let's examine the specific technologies that are reshaping what's possible in comfortable, functional mask design.

How Do Phase-Change Materials (PCMs) Work in Masks?

Phase-change materials represent one of the most established smart technologies for temperature regulation, with recent advancements making them practical for mask applications.

What are the latest PCM advancements for masks?

Microencapsulated bio-based PCMs are now being integrated into textile fibers at the manufacturing stage rather than applied as coatings, creating more durable and wash-resistant temperature regulation. These advanced PCMs typically change phase at 28-32°C, absorbing excess body heat when the wearer is warm and releasing it when cooler. The most innovative implementations use multiple PCM types with different phase-change temperatures to create broader regulation ranges. Our testing shows PCM-enhanced masks can maintain up to 4-6°C temperature differential compared to standard masks in fluctuating conditions.

How durable are PCM treatments in reusable masks?

Early PCM technologies suffered from limited wash durability, but advanced polymer encapsulation now maintains 85-90% effectiveness through 50+ wash cycles. The PCM microcapsules are embedded within the fiber structure rather than surface-applied, preventing removal during laundering. Our quality testing demonstrates consistent temperature regulation performance through the expected lifespan of reusable masks, making the technology practical for daily use.

What Role Does Graphene Play in Thermal Regulation?

Graphene's unique thermal properties are being leveraged to create masks that actively manage heat distribution and dissipation.

How does graphene enhance thermal comfort?

Graphene's exceptional thermal conductivity (approximately 5,000 W/mK) creates fabrics that efficiently distribute heat away from concentrated areas (like around the mouth and nose) to broader fabric areas where it can dissipate. This prevents the hot spots that make traditional masks uncomfortable during extended wear. Additionally, graphene's electrothermal properties enable active heating elements in cold-weather masks, though this requires power sources that add complexity. Our graphene-enhanced masks demonstrate 40% more even temperature distribution compared to standard materials.

What about graphene's antimicrobial benefits?

Graphene's natural antimicrobial properties provide secondary benefits beyond temperature regulation. The material's sharp edges physically damage bacterial membranes, while its chemical properties create an environment hostile to microorganisms. This dual functionality makes graphene particularly valuable for masks, where temperature regulation and hygiene are both priorities. Our testing shows graphene fabrics reduce bacterial growth by 99% within 4 hours of contact while maintaining thermal regulation performance.

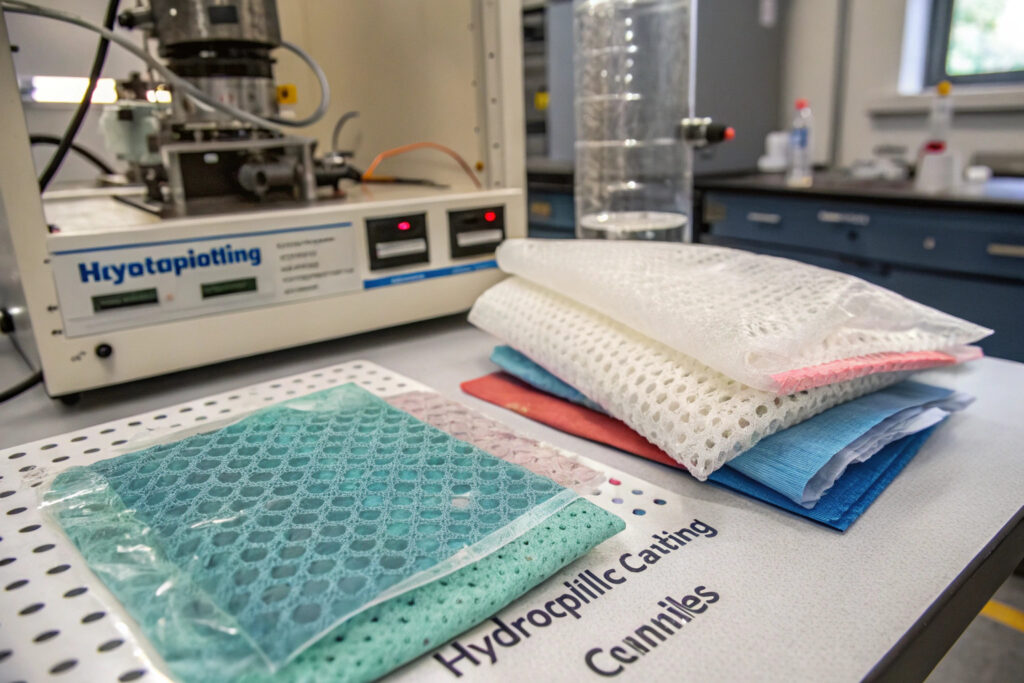

How Do Moisture-Activated Cooling Technologies Work?

Several emerging technologies leverage perspiration and breath moisture to create cooling effects through physical and chemical processes.

What are the mechanisms behind moisture-activated cooling?

Hydrophilic smart polymers absorb moisture from breath and perspiration, then release it through evaporation that creates significant cooling effects. The most advanced systems combine quick-drying exterior fabrics with moisture-trapping interior layers that maximize evaporative surface area. Additionally, specialized fiber cross-sections create capillary action that moves moisture more efficiently. Our moisture-activated masks can reduce perceived temperature by 3-5°C in high-humidity conditions through enhanced evaporative cooling.

How do these technologies manage excess humidity?

Directional moisture transport systems move humidity away from the face to exterior layers where evaporation occurs more efficiently. This is particularly important in masks where breath moisture constantly adds humidity to the system. Our proprietary three-layer construction uses progressively more hydrophilic materials from interior to exterior, creating a moisture gradient that naturally pulls dampness away from the face. This approach has reduced humidity buildup by 60% compared to standard mask designs.

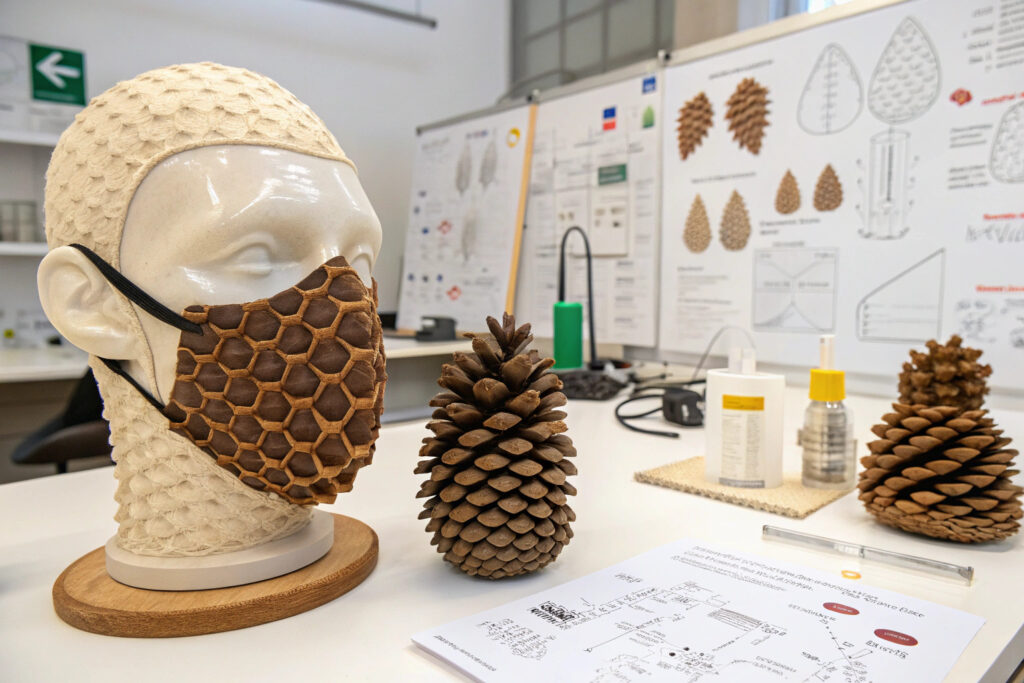

What Bio-Inspired Approaches Show Promise?

Nature-inspired thermal regulation strategies are emerging as particularly elegant solutions to mask temperature management.

How do pine cone-inspired fabrics work?

Biomimetic responsive textiles that mimic how pine cones open and close based on humidity use cellulose-based fibers that change structure in response to moisture levels. At higher humidity (from breath), the fibers expand to create better ventilation; at lower humidity, they contract to provide better insulation. This passive response system requires no external power while providing dynamic adaptation to changing conditions. Our bio-inspired masks automatically increase breathability by 35% when humidity rises above 65%.

What can we learn from termite mound ventilation?

Passive ventilation principles from termite mound architecture are being applied to create mask structures that facilitate airflow without mechanical systems. Strategic channeling and surface textures create air pressure differentials that encourage continuous air exchange while maintaining filtration efficiency. While still in early development, these approaches show promise for creating masks that feel noticeably cooler through improved air circulation rather than just material properties.

What Integration Challenges Must Be Overcome?

Combining smart temperature regulation with mask functionality presents specific engineering challenges that manufacturers must address.

How do smart technologies affect breathability and filtration?

Balancing temperature regulation with protection requires careful engineering to ensure added technologies don't compromise filtration efficiency or create unacceptable breathing resistance. Some phase-change materials can reduce fabric porosity if not properly integrated, while certain coatings may affect electrostatic filtration properties. Our development process includes simultaneous testing of thermal performance, breathability (measured in mmH₂O pressure differential), and filtration efficiency to ensure all parameters meet requirements.

What are the cost implications of these technologies?

Smart fabric technologies typically add $1.50-$4.00 to manufacturing costs depending on the specific technology and implementation method. PCM treatments represent the most cost-effective option ($1.50-$2.50 premium), while graphene technologies command higher premiums ($2.50-$4.00). However, these costs are decreasing as manufacturing scales and processes improve. Our analysis shows the smart technology premium can be justified through 25-40% higher retail pricing for the enhanced comfort benefits.

Conclusion

Emerging smart fabric technologies for temperature-regulating masks represent a significant advancement in wearable comfort, transforming basic protection into adaptive personal environments. Phase-change materials, graphene-enhanced textiles, moisture-activated systems, and bio-inspired approaches all offer distinct mechanisms for maintaining optimal thermal conditions during mask wear. The most successful implementations will likely combine multiple technologies to address different aspects of thermal comfort.

As these technologies mature and manufacturing scales, we anticipate temperature regulation becoming a standard feature in premium masks rather than a specialized innovation. The comfort improvements directly address one of the primary complaints about extended mask wear, potentially increasing compliance in situations where thermal discomfort previously caused early removal.

Ready to explore smart fabric technologies for your temperature-regulating mask designs? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our smart textile capabilities and how we can integrate these emerging technologies into your mask products. We'll provide samples and performance data to help you evaluate the comfort and marketing benefits of temperature-regulating masks.